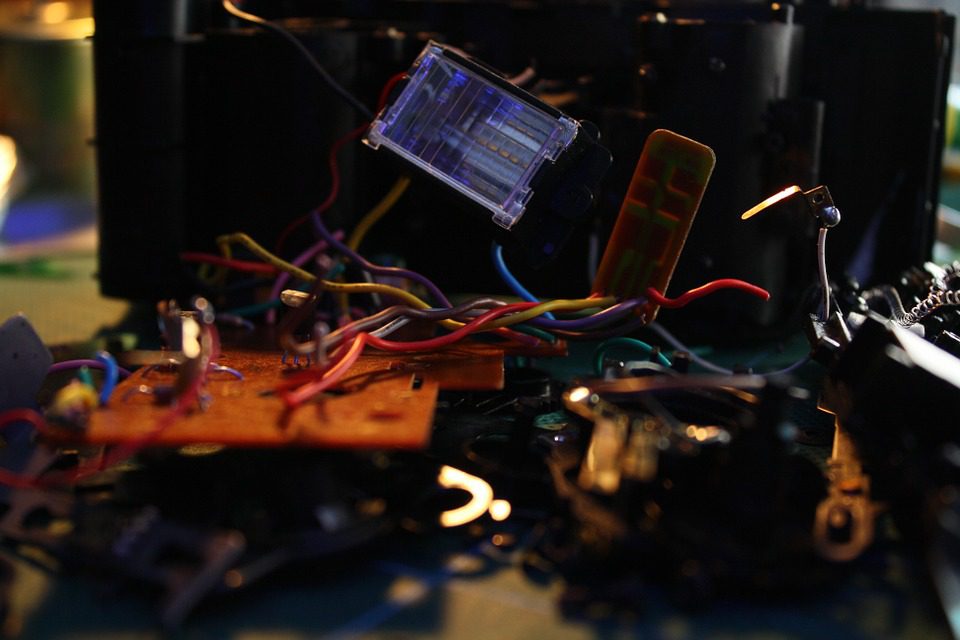

When the electronics industry was young, the components of an electronic device were soldered to each other or to terminal strips and tube sockets. Today, we use circuit boards as bases that make it far easier and cheaper to connect components.

(Pixabay / beear)

Prototype circuit boards have enabled electronic designs to be far less cumbersome. As a result, electronic devices are getting smaller and more compact at astonishing rates. The boards contain holes that hold components such as resistors and capacitors. Once they are in place, they can be soldered through automation to ensure that they are firmly anchored.

Prototype printed circuit boards are everywhere—in your computer, printer, digital clock, microwave oven, and smart phone. Though we seldom see them, printed circuit boards fuel the electronics industry.

With so many boards in use, did you ever wonder where they all end up? This question actually strikes on a major problem. There is no good resting place for PCBs because they are so difficult to recycle. Why so difficult? There are a couple of reasons:

- Each little PCB contains many different types of metals and materials that must all be recycled in different ways.

- Recycling the boards by melting can result in toxic fumes being released into the air. The fumes come from copper, which is present on most PCBs.

Thankfully, though, researchers in China and Scotland have been hard at work solving the problem of PCB disposal and are developing effective recycling methods.

China

Researchers at Shanghai Jiao Tong University have created a way to grind prototype circuit boards up (to a thickness of less than 1mm in diameter) and then use a high-voltage electric force to segregate the metallic and non-metallic materials. The resulting metal powders can then be recovered by a special vacuum with the non-metal residual being compressed into plaques to be used as a construction material. This method sidesteps the problem of heating the metals and creating poisonous fumes.

Scotland

A research team at Edinburgh University has also made headway in the quest to recycle prototype circuit boards, but their research has dealt primarily with gold. PCBs currently monopolize about 7 percent of the Earth’s available gold, and the Scotland team has discovered a simple way to retrieve that gold. They do this by placing the PCBs in a mild acid that dissolves their metal parts. After that, a special solvent helps draw the gold out of the liquid mixture. Scientists have tried similar methods in the past to retrieve gold from PCBs, but they relied on harsh chemicals that compromised the gold.

These promising developments can help ensure that the prototype PCBs that help make our lives easier will not hinder the Earth after they expire.

At EMS Solutions, we work to protect the environment by honoring lead-free standards and other environmentally-friendly industry standards.