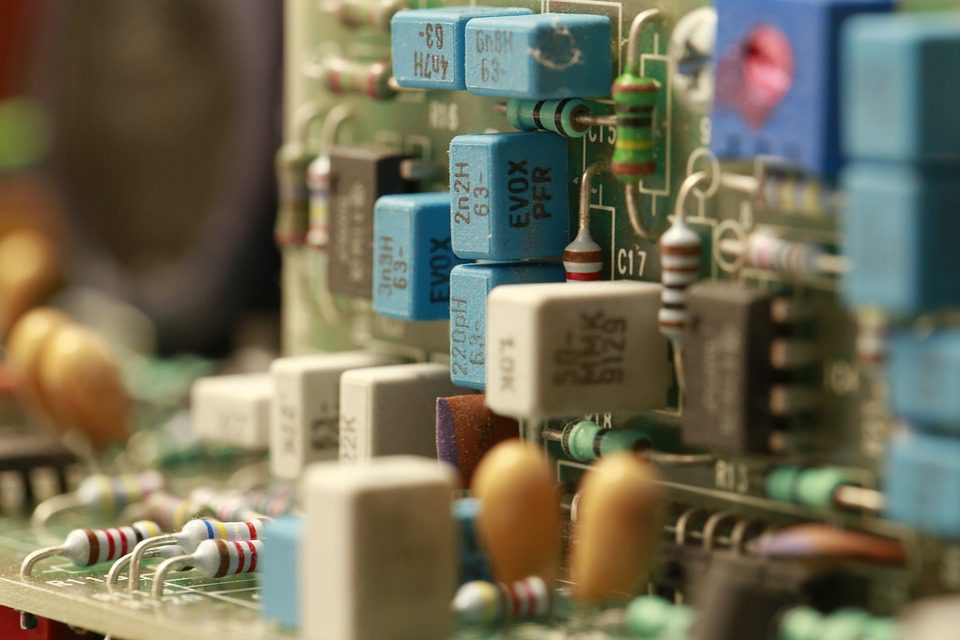

Through-hole technology used to be the primary option for circuit board design. It did the job but often clumsily. Enter surface mount technology, which allows components to be mounted directly onto the circuit boards. With SMT, you can escape the gaggle of wires previously needed to connect the upper and under sides of boards.

(Pixabay / nicola2070)

While some projects may still require through-hole methods, many others would be more efficient and durable with surface mount technology. SMT presents a host of advantages but very few drawbacks. Here are just a few of the benefits of the technology:

Fit more on your boards. Electronic components are becoming astoundingly small. SMT can support smaller parts than through-hole technologies can. That means you can load your boards up with more capabilities than ever before.

Less drilling = more strength. The holes needed for through-hole technology can cause boards to weaken and even crack. SMT requires fewer holes, which results in boards that stay strong in spite of tension.

Use the bottom of your boards. It used to be that you had to reserve the bottom of PCBs for wiring. SMT has changed that, freeing up the bottom of the board to accommodate components. That translates into a more compact final product and lower costs, too, because you don’t have to draw on additional boards to make everything fit.

Get more durable results. Boards created with through-hole methods are known for having their wires come loose with shaking or vibration. Those made with surface mount technology don’t have this problem, so they’ll last longer, even if they get jostled around in a pocket, purse, or backpack.

Make prototypes faster. With through-hole technologies, it took much longer to generate small batch prototypes. SMT does not rely on unwieldy breadboards and facilitates quicker, easier assembly line setup. With surface mount technology, you can get full prototypes in a few days.

Accommodates through-hole components. There are a few parts that don’t work well with surface mount processes, including those that put off a lot of heat. For these components, you can incorporate through-hole technologies into your SMT board production, but you can’t do the opposite. Through-hole boards cannot support SMT, making them a less versatile option.

At EMS Solutions, we specialize in printed circuit board assemblies with both surface mount and through-hole technologies. Contact us for more information about our electronics manufacturing services.