Back in the early days of printed circuit boards, customers had to wait a while for their orders to be filled. They had to fax in their purchase orders, then standby for a confirmation call or fax. That was just to get the ball rolling. By the time engineering, production, and shipping were factored in, most people were lucky to receive their PCBs in 7-10 days.

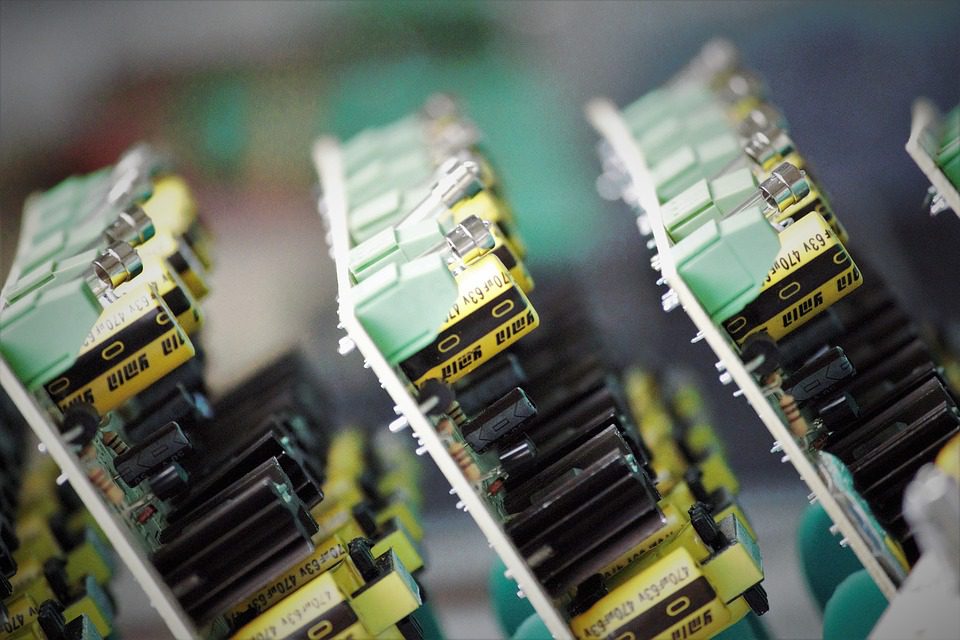

(Pixabay / ranjatm)

Two-day turnarounds on PCBs were almost unheard of in the past, but that’s not the case today. Beginning in the 1990s, people started wanting their PCBs on the double, and the industry responded by developing automated circuit board manufacturing processes. Production time was slashed, and PCBs were being returned to customers at impressive rates.

The phrase “quick-turn PCBs” is commonly used in the industry, but there seem to be different definitions of the term. This may be because there are so many variables for PCB assembly. Turnaround time depends on the number of panels in the PCB, the complexity of the design, and more. PCB makers can rush the process by paying employees overtime, bringing in weekend workers, or moving priority orders in front of others, but there’s a price to be paid for all of these strategies. And sometimes, the costs outweigh the benefits.

Defining Turn Time

As a general rule, the clock can start running on a PCB order if it is received by noon. If not, the clock won’t start until the next day. There are many steps involved in getting an order to production. It’s possible to accomplish them all by the end of the day, but if anything goes wrong, the process could derail and run into overtime. Noon is a safe cutoff.

Once an order is placed, the customer service department must receive the order, acknowledge its receipt, enter the information in the computer system, and confirm it. After the order is received, the clock will start running on turn-around time. All told, it usually takes a couple of hours to in-process an order.

After the ordering process is complete, the engineers are called in. It’s difficult to assign the engineering process a time frame. Engineers will need to review the specifications of the job and then send it to production. Time in engineering depends on the complexity of the job. Suffice to say that most jobs spend two to three hours in engineering, but they can spend many more if the order is particularly involved.

Ship dates can be calculated in 24-hour increments after the time the order was received. If the order was received after noon, shipping dates should be calculated starting at 12:00 am of the following day.