Are you looking to outsource electronics manufacturing for the first time? If so, choosing an electronics manufacturing services (EMS) partner can be a stressful experience. One mistake, and you could put your company or startup on the verge of bankruptcy.

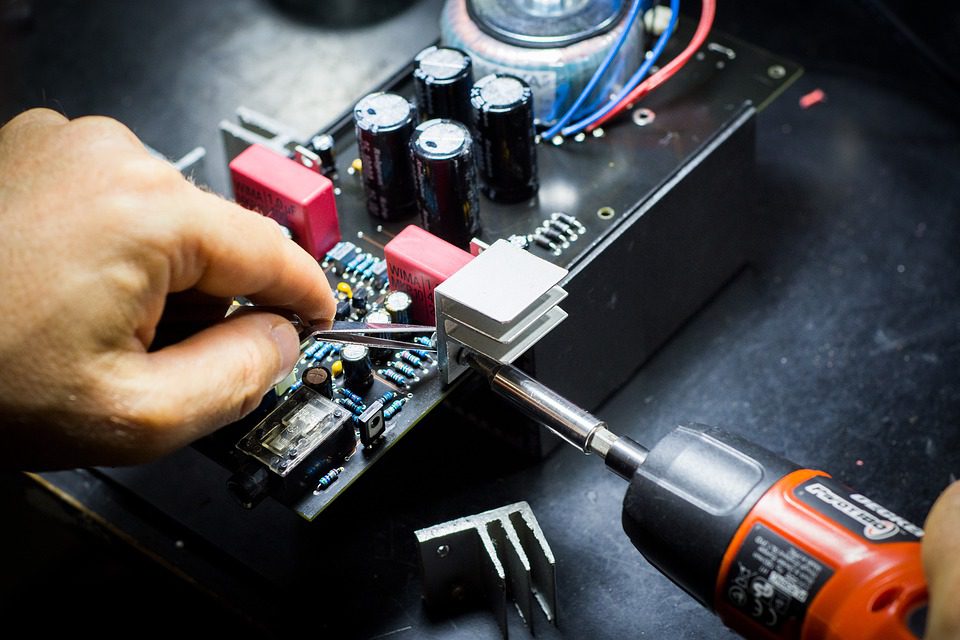

(Pixabay / www-erzetich-com)

To help you find a suitable EMS provider, we have put together a list of things that you should consider before agreeing to a manufacturing contract or partnership.

1. Years in business

Experience matters. While a brand new company might offer the cheapest rates, they may still be working out the kinks. If you’re new to outsourcing electronic manufacturing services, consider using an experienced company with a solid reputation in the industry. Don’t be afraid to ask about a perspective vendor’s business history so you can see how long they have been in business and what type of clients they have served over the years.

2. Design capabilities

It’s always best to opt for an EMS provider who has the ability to provide custom designs. Even if you have your own specifications and prototype, working with a vendor who has an eye for design can help you enhance the appeal of your board, or discover shortcomings in your design that you weren’t initially aware of. You can then redesign the whole board, which should improve your overall offering and help streamline processes.

3. Pricing

Another important thing you should know is how much the EMS provider is going to charge to design your boards. In fact, you should ask them to be very transparent about what they’ll deliver for different levels of pricing. Most of the companies will spend some time putting together a detailed quote, so you can make an Excel sheet to compare what each vendor is offering for the cost. Also, make sure you’re aware of the provider’s return policy in case any of the components turn out faulty. Leading EMS providers ensure that the customer is aware of all the potential charges and will cooperate with you until the end of the project.

4. RoHS Compliance

Did you know that an EMS vendor’s environmental footprint also impacts the credibility of their company? Make sure your potential partner is compliant with RoHS (Restriction of Hazardous Substances) and can help convert any of your project’s designs into RoHS-compliant ones. Not only is it good for the environment, but it will also improve your reputation in your industry. (Who doesn’t like ec0-friendly companies?)

5. Quality accreditations

These are critical indicators of trust, so make sure the provider you’re talking to has some to display. Examples of quality accreditations include ISO 9001:2015, IPC 610, and more. You can request that the company shares these if they aren’t already listed on their company website. Also, the quality will go beyond the accreditations possessed by each vendor. You should also look at customer reviews on their Facebook page and other digital properties to analyze the quality of their customer service, omnichannel engagement, etc.

6. Equipment and machinery

Ask the provider what sort of tools and technologies they tend to utilize when designing and manufacturing boards and electrical components. We recommend going with a company that makes use of all the latest technologies to ensure that your end product is able to stand the test of time and remains highly competitive in the industry for the foreseeable future.

7. Financial standing

Is the company you’re looking at strong on the financial front? If not, they could run into cashflow problems midway through your project. (Stranger things have happened.) Analyze the financial standing of the provider, talk to some of their component distributors, and ensure that they’re reinvesting some of their profits in modern technology and equipment. You can also talk to the existing customers of that provider to find out if they’re financially stable.

8. Quality check

Your EMS provider should never be content with manufacturing a batch order of electronics. They should also carry out testing to ensure that each board and component are up to industry standards and are highly functional and work as expected. Testing the parts for any design issues and functionality-related flaws will help them evaluate trends and identify manufacturing errors without causing their customers to waste an excessive sum of money.

9. Order fulfillment

It’s also a good idea to choose an EMS vendor who has a dedicated team available to fulfill aftermarket requirements such as remanufacturing of certain components and service demands. So, consider working with a company that offers component engineering manufacturing, obsolescence management and product lifecycle support.

10. Production tracking

Tracking is crucial within the electronics’ supply chain as it provides the capability to trace the production, match replacement parts, and recall components/products. Make sure your EMS partner has a process in place for gathering the information required by the distributors, suppliers, and manufactures. Some EMS providers will also provide their partners/customers with a tracking number that can be used to trace the status of the order.

11. Communication

Communication between you and the vendor should fall under the 3 C’s: collaboration, communication, and consistency. All of these are critical to the success of your partnership. Swift communication enables active and open dialogue, which allows both parties to make business decisions faster. Reliable EMS partners focus on compliance and ethics when it comes to communicating with their customers.

Being an electronic manufacturing services provider, we understand that you may have concerns about outsourcing these processes. In addition to meeting the criteria above, our employees are dedicated to offering superior delivery and customer service, affordable pricing, and the highest quality of manufacturing services. We respect every contract we get and honor deadlines.

Contact us today to learn how we can help meet your electronics manufacturing needs.