Manufacturers used to use toxic compounds in the production of early printed circuit boards in order to save money. Later, manufacturers caught onto the dangers that these compounds posed. As workers pressed for greater safety practices on the job, the electronics industry moved away from these toxic compounds. Research efforts helped lead manufacturers to other materials that could help them turn out comparable products without the use of harmful components.

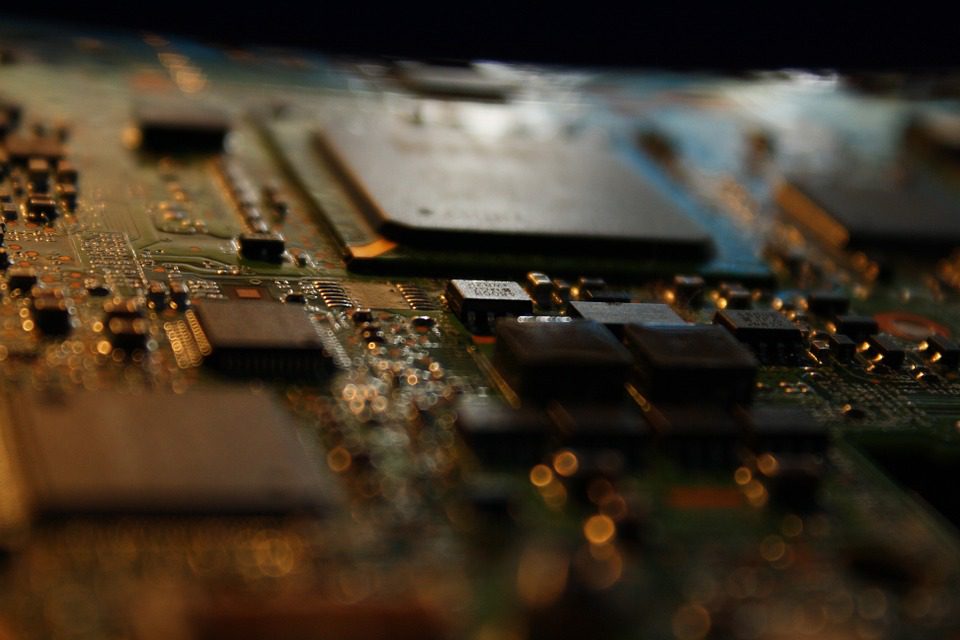

(Pixabay / beear)

Halogen is one of those dangerous components once used in PCB manufacturing. While the elements of halogen are beneficial to the products themselves, they can compromise the health of the humans who handle them in the production process. Halogen elements include astatine, bromine, chlorine, fluorine, and iodine.

Of particular note is chlorine, which has many applications in different products. It is the primary ingredient in the bleach that is used to sterilize pool water and kill bacteria. In very small and diluted amounts, chlorine protects human life from illnesses, but a concentration of the substance can pose major health risks. Exposure to chlorine may result in a variety of symptoms, which include the following:

- Persistent cough

- Vision problems

- Skin irritation

- Vomiting

- A stinging feeling in the eyes, throat, and nose

- Constricted airways

Continued exposure to this element may result in health complications, which include pulmonary edema. Chlorine is not only harmful to humans, but it also hurts the environment for a double whammy.

Bromine is another component of halogen that can be particularly insidious. While it is used to control bacterial growth and as an agricultural pesticide, exposure to high concentrations of bromine can cause watery eyes, skin irritation and burns, headaches, and dizziness.

Bromine is used as a flame-retardant in electronic devices and printed circuit boards. People working in the electronics industry face potential health risks whenever they handle products with bromine because of the fumes emitted from the melting of the plastic components.

The PCB industry is a constantly evolving one, and the search for safer source components is a critical part of ongoing industry developments.