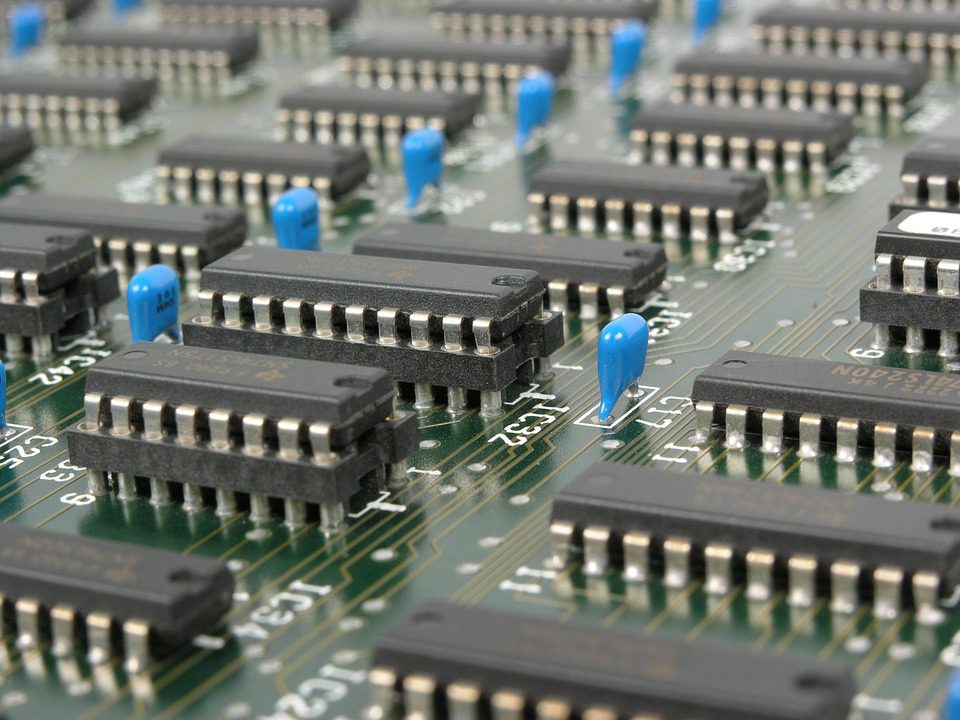

Through-hole technology is the mounting process by which component leads are placed into the drilled holes of a bare printed circuit board (PCB) and soldered to the pads on the opposite side. This can be done using manual assembly or automated insertion mount machines.

(Pixabay / Magnascan)

Through-hole technology became popular in the construction of second-generation computers in the 1950s. PCBs started as a one-sided board, then two-sided, until multi-layer boards became popular. Through-hole mounting was the standard practice until surface mount technology (SMT) became popular in the 1980s.

The advent of surface mount technology was initially thought to have made through-hole technology obsolete, but it proved to be a very resilient technology because of its distinct advantages and niche reliability.

Advantages of Through-Hole Technology

Through-hole components proved to be more reliable in products requiring stronger connections between the layers. Through-hole component leads are capable of withstanding a lot more environmental stress because they run through the board while SMT components are only secured by the solder of the board’s surface. This advantage makes through-hole technology the preferred process in aerospace and military products that endure high temperatures, extreme accelerations, and collisions. Through-hole technology is also used in applications that require testing and prototyping because of the manual replacement and adjustment capabilities.

Through-hole technology’s need for strong mechanical bonds makes the boards more expensive than SMT boards. That is why through-hole technology is now reserved mostly for heavier or bulkier components such as semiconductors or electrolytic capacitors in larger packages that need more mounting strength. They are also popular for elements like plug connectors that need a lot of muscle for reinforcement.

Most design engineers and manufacturers, including EMS Solutions, prefer the reliable through-hole technology to SMT when they are prototyping because through-hole can be used with breadboard sockets. Through-hole, however, is not appropriate for high frequency or high-speed designs that require minimal stray capacitance and inductance in wire leads.In addition, through-hole is not recommended for ultra-compact designs, which require SMT construction, even in the prototype stage.