When you create 5G electronics, your PCB design makes or breaks performance. Multilayer boards drive success in delivering the speed and reliability 5G demands. Your design decisions directly impact how well your boards handle fast signals, manage power, and control heat.

5G puts unique pressure on PCBs. You need to design boards that transmit signals without distortion, provide stable power throughout, and keep components cool despite increased density. Starting with the right design approach gives you a critical advantage.

This blog walks you through exactly what you need to consider when designing multilayer PCBs for 5G. From optimizing signal paths to selecting the right materials, we offer practical guidance you can immediately apply when working with a PCB assembly company.

(xb100/Freepik)

Understanding the Challenges of 5G PCB Design

Designing for 5G is fundamentally different from traditional PCB work. With data rates reaching multi-gigabit speeds and frequency ranges pushing into the millimeter-wave (mmWave) spectrum, even minor design oversights can result in significant performance degradation.

Multilayer PCBs are necessary to support the complexity of 5G circuits, especially for applications involving beamforming antennas, high-speed interconnects, and dense RF signal paths. These boards often contain 8, 10, or even 16 layers, each with its own purpose—some for power, some for ground, and others for high-speed routing.

What makes this particularly challenging is that high-speed signals are sensitive to impedance mismatches, dielectric losses, and crosstalk, all of which are more likely in compact multilayer designs. If you don’t manage these issues properly, your board will fail to support the data rates and signal quality required in 5G systems.

Signal Integrity: The Top Priority in 5G Multilayer PCB Design

At the core of 5G performance is signal integrity—the ability of signals to travel through the board without being degraded by noise, reflections, or interference. When you’re dealing with frequencies upward of 24 GHz, the trace geometry, spacing, and material characteristics become critically important.

To maintain signal integrity in 5G designs, you need a comprehensive approach that combines design and manufacturing considerations. This starts with using controlled impedance traces, especially for differential pairs, and precisely calculating trace width, spacing, and dielectric thickness. Modern SMT circuit board assembly techniques complement these design efforts by providing the component placement precision and consistent solder joints that minimize signal degradation at millimeter wave frequencies.

Your material selection is equally crucial—if your board uses FR-4, you’ll face more signal attenuation than if you choose a low-loss material like Rogers or Teflon-based laminates. You also have to avoid routing high-speed signals across discontinuities, such as vias or layer transitions without proper stitching. If you’re not careful, you may introduce return path interruptions that cause reflections or EMI.

Strategic Layer Stack-Up for High-Frequency Performance

The structure of your layer stack-up plays a crucial role in managing impedance, reducing crosstalk, and isolating noise-sensitive signals. In 5G designs, it’s common to dedicate specific layers to signal routing, ground, power, and shielding to keep high-frequency signals as clean as possible.

For instance, you might dedicate two inner layers to high-speed signals while sandwiching them between solid ground planes. This configuration offers excellent shielding and tightly controlled impedance, which is essential for mmWave routing. Meanwhile, power distribution can be handled on separate layers to reduce noise coupling.

A common mistake is to overcomplicate the stack-up without accounting for manufacturing feasibility or thermal performance. The more layers you add, the greater the challenge in aligning vias, balancing copper distribution, and managing heat. That’s why you need to collaborate closely with your PCB manufacturer during the stack-up design process to ensure your layout is not just electrically sound, but also producible.

Choosing the Right PCB Material for 5G Frequencies

Material selection is more than a cost or availability decision in the 5G world. You have to consider dielectric constant (Dk), dissipation factor (Df), thermal stability, and moisture resistance, all of which directly impact signal behavior at high frequencies.

If you’re designing for sub-6 GHz, you may get away with enhanced FR-4 variants. But for mmWave applications—anything from 24 GHz to 100 GHz—you’ll need low-loss, high-frequency laminates like Rogers RO4000 series, Isola I-Tera MT40, or Taconic materials. These materials offer low Df values, which means they support cleaner signal transmission over long paths.

Choosing the wrong material can completely prevent your design from functioning as intended. That’s why you need to align your material choice with your frequency requirements, board thickness, and budget early in the design cycle.

Power Integrity and Thermal Considerations

5G devices are power-hungry. As bandwidth increases, so does power consumption, and that means your multilayer PCB must support efficient power delivery while minimizing noise. You can’t rely on narrow power traces or scattered decoupling capacitors if you’re serious about 5G reliability.

Instead, you need to build solid power planes that minimize impedance and allow fast switching components to draw current without voltage droop. You should also consider using via stitching and multiple ground return paths to reduce the risk of loop currents and EMI.

Heat is another major issue in 5G designs. High-speed circuits generate localized hot spots, especially near power amplifiers or RF switches. If your board doesn’t dissipate that heat efficiently, you’ll run into thermal runaway, component stress, or failure. To address this, electronic manufacturing services often recommend including thermal vias, copper pours, and even embedded heat sinks depending on the application.

Via Design and Interconnect Reliability

In multilayer PCBs, vias connect signals between different layers, but they introduce inductance and potential signal degradation when you design them poorly. For 5G applications, you often need to use microvias or buried vias to reduce parasitic effects.

You’ll commonly find stacked or staggered microvias in high-density interconnect (HDI) designs, which you frequently use for compact 5G modules. But you must plate microvias correctly and inspect them for reliability—any voids or cracks will cause failure under thermal stress.

When you route differential pairs, avoid placing vias unevenly, as this introduces skew and degrades signal quality. Always calculate the via’s impact on impedance and include backdrilling or via stub removal techniques where necessary to maintain clean signal transitions.

EMI Mitigation and Layout Best Practices

5G signals, especially in the mmWave range, are highly susceptible to radiated emissions and electromagnetic interference. That means your PCB layout must actively mitigate EMI through shielding, spacing, and routing strategies.

For instance, you should keep high-speed signal traces away from noisy power components or switching regulators. Use ground planes and copper shielding liberally to isolate sensitive circuits. In some cases, you may need to use metal enclosures or cavity PCBs for physical isolation.

Also, avoid routing signals through areas with discontinuities, such as split planes or near mounting holes. These areas often act as antennas, inadvertently radiating energy and causing compliance issues during EMI testing.

Conclusion

As you dive deeper into 5G PCB design, you’ll realize that every design choice you make impacts signal performance, power reliability, and manufacturability. From the type of material you select to the structure of your layer stack-up and the way you route your traces, each detail plays a role in how well your product performs in real-world 5G environments.

If you want your 5G products to stand out, start by building future-ready PCBs. That means prioritizing signal integrity, collaborating with experienced EMS manufacturers, and staying up to date with materials and layout strategies that support the next generation of technology.

By approaching your design process with precision and foresight, you’ll create PCBs that not only meet the technical demands of 5G but also support scalability, longevity, and market competitiveness.

Video

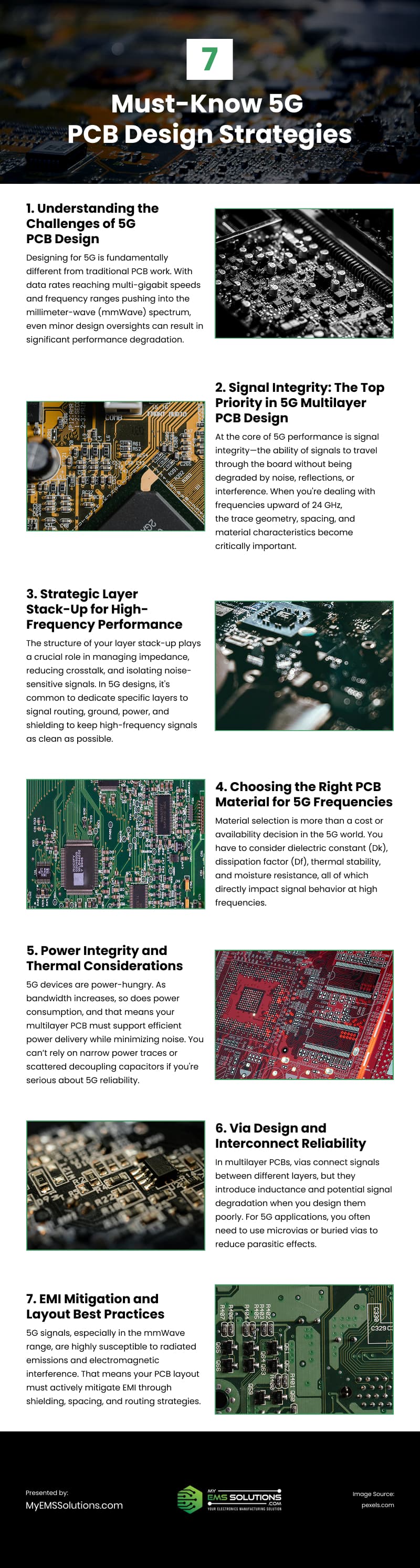

Infographic

Designing multilayer PCBs for 5G technology requires precision and advanced techniques to support ultra-high data rates and mmWave frequencies. Explore essential 5G PCB design strategies in this infographic.