When sourcing out manufacturers to produce your electronic products, it is important to make sure their expertise and capabilities match up with your requirements. Choosing the cheapest available manufacturer does not usually work out in the long run. Cost is just one of the criteria for judging a contractor. Other factors include quality assurance, on-time delivery, manufacturing capability, and acquisition of parts and inventory. The search for a manufacturing partner can take a while, but it’s imperative to do it well. Having to switch manufacturers down the road can majorly disrupt operations. On the other hand, if you choose well, your partnership with your manufacturer can endure for many successful years.

(Pixabay / olafpictures)

Some companies start their search with a request for a proposal (RFP) or request for a quotation (RFQ). From there, you will want to weight a company’s qualifications and background. In your quest to find the right electronics manufacturing service provider, consider these factors.

The assembler should have industry-standard certifications. This may include being ISO certified for quality management and RoHS compliant. Certifications imply that the manufacturer is dedicated to maintaining their standards. Related to the ISO certifications is the way an assembler handles information.

Following ISO standards, documentation is standardized and is considered part of the manufacturing process. Documentation should clearly delineate what is being done by whom. The internal communication should be transparent and understandable. Outsourcing manufacturing is not an easy decision because there is the fear that the product will not be produced according to requirements. The communication plan and the project documentation should help to dispel these fears. As part of the project documentation, the communication plan is one of the first things agreed upon. The plan includes the document flow, distribution, and escalation.

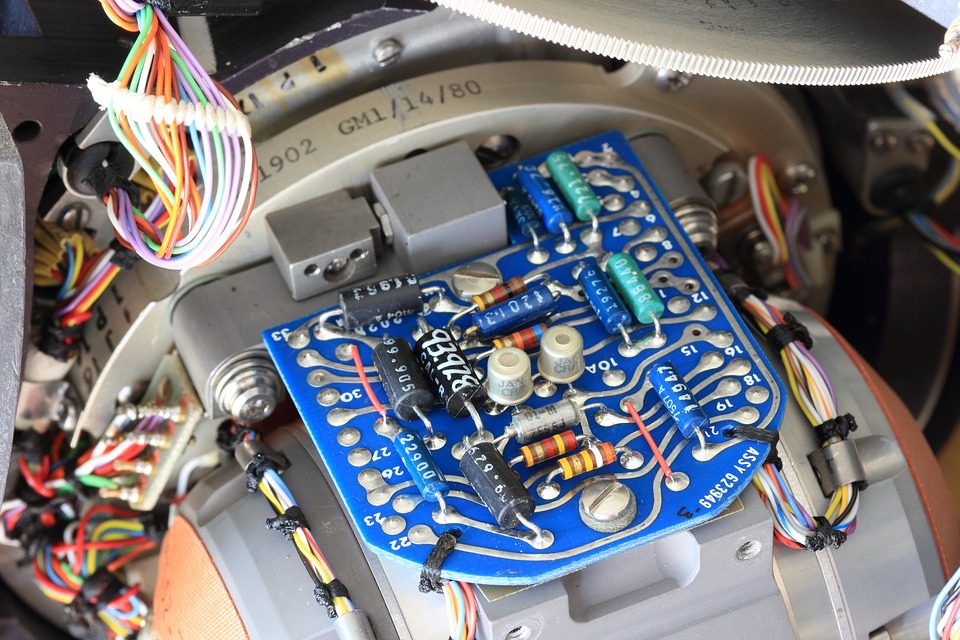

Machinery

In addition to having the right certifications, a company should also have the latest manufacturing equipment. It is the nature of electronics to be rapidly advancing. If the manufacturer is not keeping up, then they might not be able to provide the best product at competitive prices.

Financial Capacity

Besides the technical capability, the contractor should also have the financial capability to finish the project. In manufacturing, the contractor is expected to use their own finances to source materials. During the manufacturing run, and prior to any payments, they should be able to pay their own employees. Manufacturers cannot operate by relying on their client alone. This financial independence helps to keep their mind on the task at hand. As the client, this means that you have to find a company that can work on the project for several months before they are compensated. To assess their financial standing, you may want to request the submission of past financial statements and their projected collections for the following year. Other documents may include a bank certification and audit reports.

Don’t be discouraged if it takes a while to find the perfect contract electronic manufacturer. It’s worth a little extra time to find someone who will do the job professionally and who will be a dependable partner for your organization for many years to come.