If you are involved in PCB assembly, you know that even the smallest defect can compromise an entire circuit board’s functionality. One such issue that PCB assemblers often overlook until it causes a failure is tin bead formation. These tiny, stray solder particles might seem insignificant at first, but they can lead to short circuits, electrical failures, and long-term reliability issues.

Understanding why tin beads form during the assembly process can help you prevent costly defects, improve manufacturing yield, and enhance product reliability. Whether you specialize in SMT manufacturing or through-hole PCB assembly, identifying and eliminating the root causes of tin bead formation helps ensure that your PCB designs perform reliably in real-world applications.

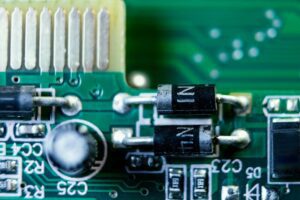

(freepik/Freepik)

What Are Tin Beads and Why Do They Matter?

Tin beads (or solder balls) are tiny metal spheres that form during the soldering process. You’ll spot them between circuit traces, on component leads, or around solder pads, but most technicians miss them until they cause functional problems. In high-density PCB designs with minimal spacing, these beads significantly increase the risk of electrical shorts.

Even when tin beads don’t immediately affect your PCB’s performance, they create hidden failure risks that worsen over time. When your circuits face humidity, vibration, or temperature changes, these particles can shift position and create unexpected connections, resulting in frustrating intermittent failures or complete circuit breakdown.

If electronic printed circuit board assembly or quality control falls under your responsibilities, you should prioritize reducing tin bead formation. This approach helps ensure your products comply with industry standards like IPC-A-610 while preventing costly product recalls, unnecessary rework, and warranty claims.

Causes of Tin Bead Formation in PCB Assembly

1. Excessive Solder Paste Application

One of the primary reasons tin beads form is overprinting of solder paste. During the stencil printing process, excessive paste application leads to unintended solder accumulation, which does not fully coalesce during reflow. Upon heating, this excess solder can form small beads rather than creating a stable solder joint.

To prevent this, you need to focus on two key areas: proper stencil design and paste application technique. First, ensure your stencil apertures match your board design exactly. Second, control your solder paste volume with precision. You can reduce tin bead formation by adjusting stencil thickness, using lighter squeegee pressure, and perfecting the paste rolling motion.

2. Poor Stencil Design or Alignment Issues

Stencils with poor designs cause uneven paste deposition, creating areas with excess solder that form tin beads. When your stencil misaligns during printing, solder paste lands in unintended areas, which increases solder balling after reflow.

You should optimize stencil alignment and apertures specifically for your component layout. Modern PCB assembly operations rely on laser-cut stainless steel stencils with nano-coatings that improve paste release and reduce the deposition inconsistencies that lead to tin beads.

3. Incorrect Reflow Soldering Profile

Reflow soldering is one of the most critical steps in PCB assembly, and an improper thermal profile can significantly influence tin bead formation. When assemblers fail to optimize the ramp-up rate, soak time, or peak temperature, they face the risk of excessive solder splattering that may lead to bead formation.

A rapid temperature rise can cause solder paste to explode and disperse rather than flowing smoothly into the solder joints. Likewise, a slow ramp-down phase can allow molten solder to migrate, increasing the risk of small beads forming around components.

By carefully analyzing and optimizing your reflow oven settings, you can ensure uniform solder melting and solidification, minimizing unwanted bead formation while improving overall solder joint quality.

4. Contamination and Surface Tension Imbalances

Contamination creates serious problems during PCB assembly. When PCB surfaces or component leads contain impurities, solder won’t flow properly. This leads directly to uneven adhesion and beading issues. The most common culprits include oxidized pads, leftover flux, and moisture—all of which change how molten solder behaves. Instead of forming solid joints, the solder breaks apart into tiny beads.

You can prevent these problems with proper preparation. Always ensure PCBs and components stay clean and oxidation-free before assembly begins. Choose no-clean or low-residue flux products that maintain good solderability without leaving troublesome residue behind.

How to Prevent Tin Bead Formation in PCB Assembly

1. Optimize Stencil Printing and Solder Paste Application

One of the most effective ways to prevent tin bead formation is by controlling solder paste volume through precise stencil design and application techniques. You can achieve this by:

- Using step-down stencils to reduce paste deposition on fine-pitch components.

- Selecting the correct stencil thickness and aperture size to match the PCB layout.

- Ensuring proper stencil cleaning between prints to prevent paste buildup.

By optimizing these factors, you reduce excess solder accumulation while significantly lowering the chances of tin bead formation.

2. Fine-Tune Reflow Profiles for Consistent Soldering

A well-calibrated reflow soldering profile is essential for achieving smooth solder flow and preventing bead formation. To accomplish this, you should:

- Ensure the preheat phase gradually removes solvents from the solder paste, reducing splattering.

- Use a controlled peak temperature that fully melts the solder without excessive turbulence.

- Allow a slow, controlled cool-down period to stabilize solder joints and prevent migration.

Regularly monitoring and adjusting your reflow oven settings will help maintain consistent soldering quality while eliminating conditions that lead to tin bead formation.

3. Maintain a Clean and Contaminant-Free Assembly Process

The cleanliness of your PCB assembly environment directly impacts soldering quality. To minimize tin bead risks, follow these best practices:

- Store PCBs and components in moisture-controlled environments to prevent oxidation.

- Use anti-static and cleanroom protocols to reduce contamination risks.

- Implement a flux management strategy that prevents excessive residue buildup.

By maintaining a clean and well-controlled assembly process, you reduce unpredictable soldering defects and prevent tin beads from compromising your PCB’s performance.

Final Thoughts

Tin bead formation in PCB assembly might seem like a minor issue, but you shouldn’t ignore its long-term impact on circuit reliability, functionality, and manufacturing yield. Whether you are assembling low-volume prototypes or mass-producing PCBs, preventing tin bead formation requires a multi-faceted approach that involves optimizing solder paste application, refining reflow soldering profiles, and maintaining clean assembly environments.

By identifying and eliminating the root causes of tin bead formation, you not only enhance the quality of your printed circuit board assembly but also reduce failure rates and increase product lifespan. With careful process control and continuous quality improvements, you can ensure that your PCBs remain defect-free and meet the highest industry standards.