Launching an electronic product comes with its own set of challenges, with cost optimization being a crucial one. This is particularly true when it comes to components like printed circuit boards.The key is to tackle this issue head-on, right from the design stage.

By integrating cost-saving measures into your design and production processes, you can keep expenses in check. This post will walk you through these strategies, ensuring your product launch is both cost-efficient and of high quality.

(freepik/Freepik)

1. Opt for Surface Mount Technology (SMT)

A key tip for cutting costs is to pick Surface Mount Technology (SMT) instead of Through-Hole Technology (THT) for your PCBs. SMT is usually cheaper and uses less space. THT might be stronger, but it’s more expensive, and you might not need that extra strength for your product.

Using SMT makes putting your PCBs together faster and easier. It’s about sticking parts right onto the PCB surface, which speeds up the whole assembly line. This means you spend less on labor and get things done quicker.

2. Adopt a common platform architecture

Adopting a ‘common platform architecture’ means using the same components for similar needs across different products. This approach simplifies your inventory (fewer different parts to stock), streamlines training for technicians, and enhances manufacturing efficiency.

Take the example of a smartphone manufacturer who uses the same basic circuitry across various models, differing only in exterior design or screen size. This standardization in core components results in substantial savings in production costs and time, as it allows for bulk purchasing and a more streamlined manufacturing process.

3. Eliminate unnecessary features

Over-engineering can lead to unnecessary costs in product design. Keep it simple by focusing on essential features that meet user needs. For instance, using a standard wireless module instead of a high-tech one can greatly reduce costs if advanced connectivity isn’t crucial.

This approach not only lowers expenses but also eases the manufacturing process. Plus, streamlining your design to include only necessary components can significantly cut down on your Bill of Materials and overall product complexity.

4. Consider panelizing the PCBs

Another way to cut costs for your electronics product launch is by panelizing PCBs. This works well if your PCBs are either small or have a unique shape. Think of it like grouping several smaller boards on one larger panel. It makes them easier to handle during manufacturing and adds stability, especially important for oddly shaped boards.

This method is key for efficiency. It allows you to manufacture multiple boards at the same time, which saves on labor and machine time. For small or intricate PCBs, it also reduces the chance of damage. By streamlining the process, panelizing directly helps in keeping your production costs down.

5. Avoid single-source or end-of-life components

Avoid relying on single-source components or those nearing the end of their life-cycle in your product design. The risk here is future availability – if these parts become scarce, you could face skyrocketing prices and challenges in finding replacements. This scenario can quickly inflate your production costs and delay your launch.

To mitigate this risk, it’s wise to consider alternatives right from the start. You can ask an EMS solutions provider to suggest viable replacements for these components. Taking this step keeps your costs lean—a benefit you can pass onto your customers.

6. Integrate energy efficiency into design

Could making your product more energy-efficient be the key to cost optimization? Absolutely. Designing for lower power consumption lets you use smaller, cheaper batteries or power sources. This not only cuts down your production costs but also results in a sleeker, more compact product.

And there’s a bonus for your customers too. Energy-efficient products are cheaper to run, a big draw for energy-conscious buyers. So, by focusing on energy efficiency, you’re not just saving on manufacturing costs. You’re also making your product more appealing and affordable for the long haul.

7. Go modular

Facing the challenge of rapid tech advancements? Consider a modular design for your electronic product. This approach involves creating components that are easily upgradable or replaceable. Imagine your product is a smart device—if you can update its memory or processor later, you have a competitive edge.

This strategy offers a practical solution: it not only future-proofs your product but also reduces future development costs. Instead of redesigning a new model for every tech advance, you simply upgrade the necessary parts. It’s an efficient way to keep your product relevant and cost-effective in the fast-evolving electronics market.

8. Choose smaller components

When planning your electronics product launch, think about using smaller component sizes like 0402s or even 0201s. Why? These tiny parts take up less space on your PCB assembly, which is great for sleek, compact designs. Plus, they’re usually cheaper than bigger components, like 0603s or 0805s, which are slowly getting outdated.

A quick tip: If a manufacturer suggests going for larger components to save costs, take a second look. It could mean they’re not too confident handling the small stuff. A good manufacturer should be able to work with these smaller sizes efficiently, helping you keep your product small, cost-effective, and up-to-date with current technology trends.

Cost optimization is crucial in launching your electronic product successfully. Each strategic decision, from component selection to design and manufacturing, directly impacts your budget. By focusing on these key areas, you set up your launch to be financially viable and appealing to your target audience. Remember, it’s the smart, informed choices that pave the way for a successful and cost-effective market entry.

Video

Infographic

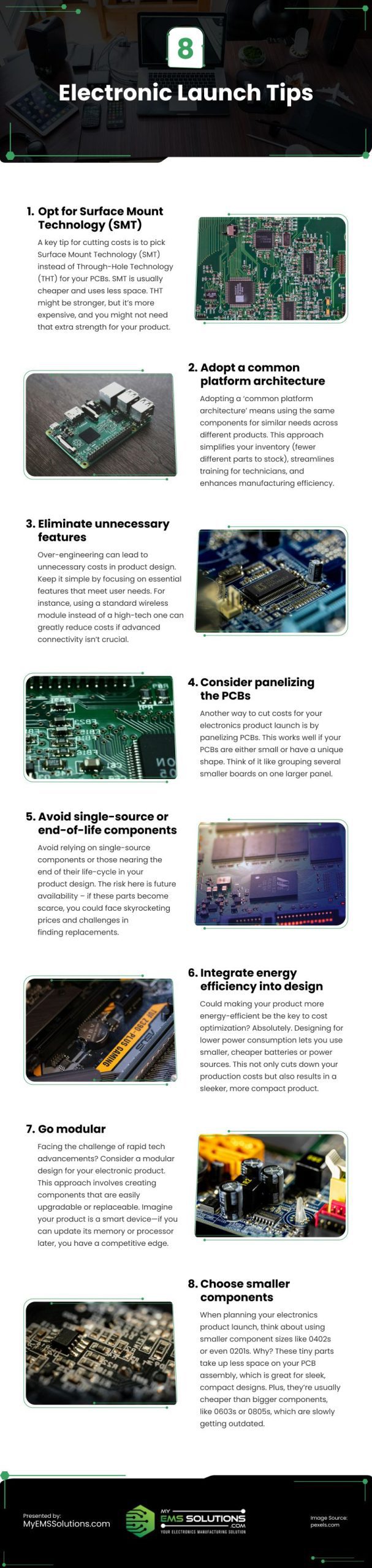

Launching an electronic product can be challenging, especially with components like printed circuit boards. Integrating cost-saving measures into your design and production processes can help keep expenses in check. This infographic guides you through cost-efficient, high-quality product launch strategies.