Electronics keep changing, and sometimes you need to copy a circuit board instead of starting from scratch. That’s where PCB cloning comes in. It’s a process that duplicates an existing printed circuit board (PCB) so you can manufacture more of the same design or improve on it. Whether you’re dealing with outdated parts, lost design files, or production costs, cloning gives you an option to move forward.

(freepik/Freepik)

What Is PCB Cloning?

PCB cloning, also called PCB duplication or PCB reverse engineering, is the process of copying an existing circuit board. This includes replicating the board layout, components, and electrical connections. Companies use it to maintain legacy equipment, create custom modifications, or streamline production.

The process requires:

- Extracting the board’s design, including traces, layers, and components

- Rebuilding the schematic diagram

- Recreating the bill of materials (BOM)

- Generating new fabrication files for manufacturing

With PCB cloning, manufacturers can continue producing a board even if the original design is unavailable or obsolete.

Why Clone a PCB?

There are a few reasons why companies choose PCB cloning over designing a new board:

1. Replacing Obsolete Boards

If a PCB is no longer in production, cloning allows you to reproduce it for repairs and replacements. This is common in industrial equipment, military hardware, and medical devices where changing the design isn’t an option.

2. Cost Savings

Developing a new PCB from scratch takes time and money. Cloning eliminates the need for redesigning, prototyping, and testing. You get an exact copy of a working board without going through the entire development process.

3. Streamlining Production

A PCBA manufacturer can optimize production by cloning older PCBs. They built the original board with outdated methods, but cloning updates it for modern assembly techniques like automated through-hole assembly or SMT manufacturing.

4. Customization

Sometimes, a PCB works well but needs modifications. Cloning allows you to make small changes—like upgrading components or improving efficiency—without designing a new board from scratch.

How PCB Cloning Works

Cloning a PCB requires careful analysis and precision. Here’s how the process works:

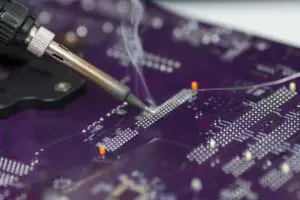

Step 1: Reverse Engineering the Board

Engineers inspect the PCB layout, identify components, and trace electrical connections. For complex boards, they use X-ray inspection to reveal hidden layers and traces.

Step 2: Creating the Schematic

After mapping the board, engineers rebuild the schematic diagram. They ensure all components interact correctly and adjust any inefficiencies to improve performance.

Step 3: Rebuilding the BOM

The bill of materials (BOM) lists all components on the board. If some parts are unavailable, engineers find replacements that maintain functionality.

Step 4: Generating Fabrication Files

With the schematic and BOM ready, engineers create new Gerber files for manufacturing. These files ensure the cloned board matches the original in every detail.

Step 5: Prototyping and Testing

Manufacturers produce a prototype and test it to confirm it works like the original. If QC calls for it, they fine-tune the design before full-scale production.

PCB Cloning In Different Industries

Cloned PCBs appear in industries where downtime is costly or redesigning isn’t practical.

Medical Devices

Hospitals and labs rely on specialized equipment that can last decades. When a PCB fails and replacements don’t exist, cloning keeps critical machines running.

Industrial Automation

Factories use automated systems with older PCBs. Instead of redesigning an entire control system, companies clone existing boards to keep production lines operational.

Military and Aerospace

Defense and aerospace projects have strict requirements. Many systems still use older PCBs that need maintenance or upgrades without altering certified designs.

Consumer Electronics

Some businesses clone PCBs to create custom versions of popular devices or replace mass-produced boards with upgraded versions.

Challenges in PCB Cloning

While PCB cloning solves many problems, it comes with challenges:

Component Availability

Some components go out of production. Engineers must track down substitutes that match the original specs. If they choose the wrong part, the board may not function as expected.

Legal Considerations

Some companies hold patents or copyrights on PCB designs. If a manufacturer copies a board without permission, they risk legal trouble. Before cloning a PCB, companies must confirm they have the right to reproduce it.

Precision and Accuracy

Cloning requires exact duplication. Engineers must carefully map every trace and place each component correctly. A small mistake in the layout or connections can cause failures.

Choosing a PCB Cloning Service

If you’re outsourcing PCB cloning, look for a provider with:

- Experience in electronic manufacturing services (EMS PCB assembly)

- A proven track record in PCB assembly outsourcing

- Expertise in lead-free PCB assembly and RoHS compliance

- Strong reverse engineering capabilities

Reliable manufacturers ensure that cloned boards match the original in performance and durability.

Conclusion

PCB cloning keeps production moving when redesigning isn’t practical. Whether you’re maintaining older equipment, cutting costs, or improving an existing board, cloning gets the job done without unnecessary hassle.

Thinking about cloning a PCB? Find a manufacturer that knows reverse engineering and PCB assembly inside out. Make sure they can handle everything from sourcing components to meeting compliance standards. The right partner makes sure your new board works just like the original.

Video

Infographic

PCB cloning efficiently reproduces or improves circuit boards by reverse-engineering existing designs. It’s ideal when original plans are unavailable or outdated. This infographic highlights why companies prefer PCB cloning over starting new designs.