PCB etching is a highly intricate process that’s crucial for the fabrication of printed circuit boards. It helps produce the final circuit pattern by effectively removing copper from the PCB. Although many other processes need to be carried out before you can finalize the board, the etching process prepares the board for the last stages of fabrication.

Although you can perform etching in any setting, the process can be somewhat complex if you’ve never dealt with it before. This article breaks down etching as it applies to PCBs, including its definition, types, and application steps.

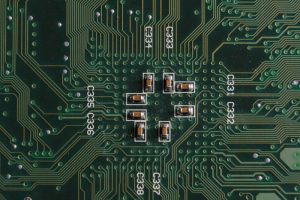

(Tima Miroshnichenko/Pexels)

What Is PCB Etching?

PCB (printed circuit board) etching is the process of removing unwanted copper from a PCB to create the desired circuit pattern. The most common method of PCB etching is through the use of a chemical solution, such as ferric chloride.

The PCB is coated in a photoresist material, which is then exposed to UV light through a film mask, hardening the exposed areas. The board is then placed in the chemical solution, which etches away the unprotected copper, leaving behind the desired circuit pattern.

What Are the Different Types of Etching?

Laser Etching

The laser etching process allows for the precise removal of unwanted copper from a PCB to create the desired circuit pattern. The process typically involves the use of a focused laser beam directed at the PCB, which selectively removes the copper in the areas where the circuit pattern is to be formed. This allows for the creation of highly detailed and complex circuit patterns with a high degree of precision and accuracy.

Laser etching is also a non-contact process, meaning that it does not generate any mechanical stress on the PCB. This helps reduce the risk of deformation and eliminates the use of chemicals. As a result, this method of etching is a viable option for a PCB assembly company looking to reduce its carbon footprint.

Wet etching

Wet etching involves using a chemical solution to dissolve unwanted copper. The process can be broken down into:

Alkaline etching

Alkaline etching uses an alkaline solution, such as sodium hydroxide, to remove unwanted copper from the printed circuit board. The process typically involves immersing the PCB in the solution, which selectively removes the copper in the areas where the circuit pattern is to be formed.

Manufacturers typically perform alkaline etching in a high-pressure, conveyorized chamber to improve the accuracy and efficiency of the process. Exposing the PCB to a refreshed spray of etchant within the chamber results in less toxicity than in other etching methods.

Acidic etching

Acidic etching involves using an acidic solution, such as ferric chloride or cupric chloride, to etch away the copper from the PCB. The acid solution is applied to the PCB using a variety of methods, such as dipping, brushing, or spraying.

During the etching process, the acid solution reacts with the copper, causing it to dissolve and come away from the PCB. The PCB is then washed and dried to remove any remaining acid solution. In general, the acidic method works best for inner layers because the acid won’t damage the required parts. Plus, it helps minimize the lateral erosion of the etched material beneath the protective tin (lead layer).

Dry etching

Dry etching is a PCB etching method that uses a physical process rather than a chemical process. Rather than using a liquid etchant, dry etching uses a physical process like plasma etching to remove the unwanted copper from the PCB.

In plasma etching, a gas such as chlorine or fluorine is ionized to create a plasma, which is then directed at the PCB to remove the copper. The plasma etches the copper by physically sputtering it away rather than dissolving it like in wet etching.

Dry etching is a more precise method of etching PCBs than wet etching, and it can be used to create finer features and more complex circuit patterns. However, it is also generally more expensive and requires specialized equipment. Additionally, it may have some drawbacks, such as generating more waste materials.

How to Etch a PCB?

Etching a PCB requires taking the following steps:

- Prepare the PCB: Clean the PCB thoroughly to remove any dirt, oil, or other contaminants. Then, use a masking material (such as a photoresist film or liquid) to cover the areas of the PCB where you want the copper to stay.

- Choose an etching technique: Choose from dry, laser, and wet etching. If the etching method involves using a chemical, cover the entire surface of the PCB using a brush or spray bottle.

- Monitor the etching process: Keep an eye on the PCB as it etches. The amount of time it takes for the etching to be completed depends on the type of etchant, the PCB thickness, and the temperature of the solution.

- Rinse the PCB: Once the etching is complete, rinse the PCB thoroughly with water to remove any remaining etchant solution.

- Remove the masking material: Once the PCB is dry, remove the masking material to reveal the finished PCB.

- Clean the PCB: Use alcohol or degreaser to remove any leftover residue from the printed circuit board.

- Perform an inspection: Inspect the PCB to ensure that the circuit pattern is accurate and that there are no defects or problems.

- Apply solder mask: Though not necessary, applying a layer of solder mask can provide insulation while safeguarding the copper traces.

Ready to etch your PCBs?

Now that you know how PCB etching works, it’s time you consider it for your assembly. Whether you’re working with an EMS company or handling everything solo, etching can help you create very fine and precise circuit patterns. You can also use it to manufacture large numbers of PCBs quickly and efficiently, making it suitable for high-volume production. Compared to other methods of creating circuit patterns, such as wire wrapping or point-to-point construction, etching is relatively inexpensive.

Video

Infographic

The creation of printed circuit boards depends on the complex PCB etching process. By successfully removing copper from the PCB, it aids in the production of the final circuit layout. Etching may be done anywhere, but if you’ve never done it before, the procedure might be a little challenging. This infographic explains PCB etching, including its description, kinds, and application procedures.