There are two methods of construction of electronics circuits: the non-automated method and the automated assembly. The non-automated method is referred to as point-to-point circuit board construction, while the automated (the current norm) is referred to as the printed circuit board.

Point-to-point Wiring

Point-to-point or hand wiring is traced back to the time when electrical assemblies employed wire nuts or screws to hold wires to an insulated ceramic or wooden board. The end product was prone to failure due to corrosion in contacts or mechanical loosening of the nuts or screws. The improvement to this version involved welding copper in the bus-bar circuits, which proved to be very expensive.

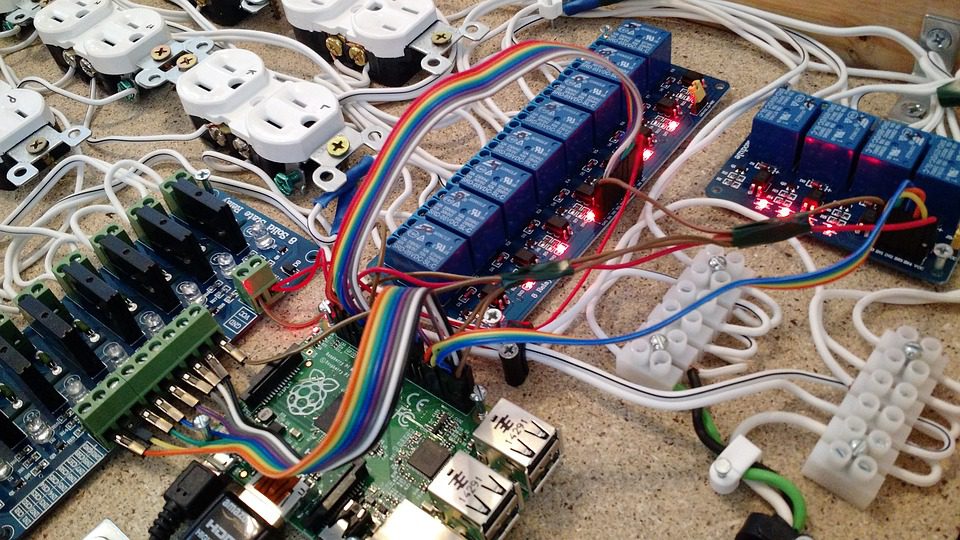

The modern version of point-to-point construction uses tag boards or terminal strips, sometimes called turret board. It involves soldering to the electrical assembly, using an alloy of lead and tin or bismuth and tin. The soldering alloy is melted to adhere to non-molten copper or tinned steel. This enables strong mechanical and electrical connection.

Point-to-point circuit board wiring is ideal when building a prototype or a customized, one-of-a-kind board. Point-to-point circuit board, which in essence is a hand-wired board, has less capacitance between conductors since the connections are separated by air (not by fiberglass as in the printed circuit board). Design and production of point-to-point circuit boards are time consuming.

Printed Circuit Board Wiring

A printed circuit board electrically connects, through mechanical support, electronic components through the use of conductive tracks or pads etched from sheets of copper that are laminated into a non-conductive substrate. Electrical components, such as capacitors and resistors, are then soldered onto the printed circuit board.

Printed circuit board may be single-sided, double-sided, or multi-layer. The electrical conductors on the different layers are connected using vertical interconnection access. Multi-layer printed circuit boards are capable of higher component density.

Printed circuit boards are the norm in most electronic products. They are popular because manufacture and assembly are automated. Producing printed circuit boards is faster and cheaper with minimal wiring errors.

Surface-mount Technology

Surface-mount technology (SMT) is the method of manufacturing circuit boards where the components are placed or mounted directly onto the surface of the printed circuit boards. The resulting device is called a surface-mount device (SMD).

EMS Solutions has four surface-mount technology lines. They employ state-of-the-art, efficient, and high-speed lines that turn out high-quality products. The SMT lines at EMS Solutions are supported by Automated Optical Inspection (AOI) equipment, an automated through-hole-placement technology, as well as other advanced support equipment. Certified and experienced technicians who are committed to produce top quality printed circuit boards operate each line.