It’s no secret that humanity has slowly been killing the earth for centuries. However, we have seen the error of our ways and taken certain measures to minimize our toxic footprint.

(Pixabay / Xlinks)

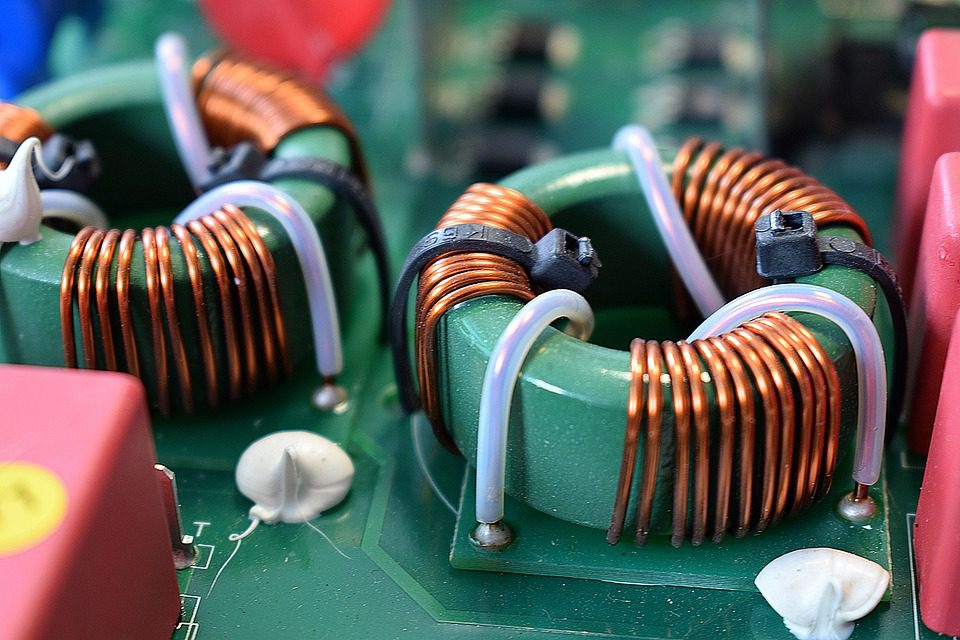

One thing that has been polluting our planet is the use of various materials in the manufacturing of electronic devices.

To take control of this problem, the European Union adopted the Restriction of Hazardous Substances Directive (RoHS) in 2003. This directive also became law in the U.S. on July 1, 2006.

In this post, we’ll discuss the importance and characteristics of RoHS-compliant PCBs. But before we get started, let’s take a look at how the RoHS directive came to be and what it aims to achieve:

What is the RoHS Directive and Why Was it Established?

The RoHS Directive, also known as the “lead-free directive,” is an initiative that regulates the use of certain toxic materials during the manufacturing of electronics.

Initially, it only restricted the use of six toxic metals. However, in 2015, four more substances were added to the list.

These substances that are commonly used to produce electronic components, such as PCBs, are all extremely hazardous to humans and animals.

Piles of electronic waste often end up in open landfills. If these sites are not properly managed, fires (due to the improper burning of waste or malicious/accidental instigation) can occur. The toxic materials in electronic waste can then release harsh chemicals into the air that pose health risks to living beings.

Rainwater can also cause these chemical materials to flow into water bodies that may be used for human consumption.

The RoHS Directive was established to regulate the use of these toxic substances in an attempt to minimize the harm they cause to all living things.

To give you a better understanding of the importance of this initiative, let’s discuss the complete list of restricted substances and the dangers they pose:

1. Lead

Lead is a soft, workable chemical element with a relatively low melting point. For this reason, it has always been a common solder material used in the production of PCBs.

However, lead is an extremely harmful substance with carcinogenic properties. Exposure to lead can cause serious health damage, such as:

- Impaired brain development (especially in children);

- Anemia;

- Kidney disease;

- High blood pressure;

- Heart disease; and

- Reduced fertility.

Before the implementation of RoHS, the most common PCB surface finishes generally contained 40% lead. The RoHS now restricts the use of lead to 0.1%, with a few exemptions.

2. Cadmium

Cadmium is a metal that has chemical similarities to zinc and mercury. In the past, it has been used in electroplating and as a plastic stabilizer, among other things.

Exposure to this toxic metal can cause cancer, and it also affects the neurological, cardiovascular, respiratory, gastrointestinal, reproductive, and renal systems in the human body.

The maximum amount of cadmium according to RoHS regulations is 0.01%.

3. Mercury

Mercury, also known as quicksilver, is the only heavy metal that keeps its liquid form at standard temperature and pressure conditions.

It’s high density and ability to conduct electricity has made it a useful component in electrical switches and relays. However, it’s one of the most toxic elements out there.

Even exposure to small amounts of Mercury can cause severe harm to your health, such as:

- Insomnia and memory loss;

- Toxicity in the central and peripheral nervous systems;

- Neurological and behavioral disorders;

- Cancer;

- Kidney failure; and

- Impaired neurological development.

The maximum amount of mercury allowed by the RoHS Directive in the manufacturing of electrical components is 0.1%.

4. Polybrominated Biphenyls

Polybrominated biphenyls (PBBs), also known as brominated biphenyls, are groups of man-made chemicals that contain polyhalogenated derivatives of a biphenyl nature.

Though PBBs were once commercially used in printed circuit boards as flame retardants, their use is now limited to 0.1% by RoHS regulations.

This is because PBBs are known to cause cancer and also affect the endocrine system in humans.

5. Polybrominated Diphenyl Ethers

Polybrominated diphenyl ethers (PBDEs) were also once used as flame retardants in various applications, including electronics.

Some studies have found that these organobromine compounds can disrupt the endocrine system and may also lead to thyroid, liver, and neurodevelopmental dysfunction.

Because of their hazardous properties, the RoHS restricts the use of PBDEs in PCB production to 0.1%.

6. Hexavalent Chromium

Hexavalent chromium is the chemical element that forms part of all chemical compounds containing chromium in the +6 oxidation state.

This material was traditionally used to coat electrodeposited copper foils used in PCBs to protect them against corrosion.

Known side effects of this hazardous substance are:

- Lung, nasal, and sinus cancers;

- Liver and kidney damage; and

- Skin ulcerations.

To contain the health risks of hexavalent chromium, the RoHS has determined that no more than 0.1% of this material may be used in PCB manufacturing.

7. Bis(2-Ethylhexyl) Phthalate

Bis(2-ethylhexyl) phthalate, also called DEHP, is a colorless viscous liquid that is commonly used as a plasticizer in the vinyl insulation of electrical wires.

Studies have found that this substance can potentially cause endocrine, testicular, ovarian, renal, and neurotoxicity.

Therefore, it was added to the RoHS Directive’s list of restricted substances in 2015.

8. Benzyl Butyl Phthalate

Benzyl butyl phthalate (BBP) is another clear liquid that has been used as a plasticizer in the PCB industry.

Though the toxicity of this substance is still being researched, it has been found to affect fetal health and development. Because of this, the RoHS now also restricts the use of BBPs in electronic devices to 0.1%.

9. Dibutyl Phthalate

Another plasticizer that is regulated by the RoHS Directive is dibutyl phthalate (DBP).

In November 2006, this substance was added to the California Proposition 65 (1986) as a suspected teratogen. It is also believed to have a negative impact on the endocrine system, and has therefore been added to the RoHS Directive’s list of restricted materials.

10. Diisobutyl Phthalate

Diisobutyl phthalate (DIBP) has properties that make it very similar to DBP. However, it has a lower density and freezing point than DBP and is also odorless.

Because of its excellent stability in regards to heat and light, as well as its affordability, it has been a popular plasticizing substitute for DBP.

Research has shown that DIBP has the potential to be embryotoxic and teratogenic, and could also affect reproductive organs. Therefore, it’s usage is also restricted to 0.1% by the RoHS Directive.

Conclusion

Now that you know the importance of controlling the use of toxic substances in the production of PCBs, you may want to ensure that you only use boards that are RoHS-compliant.

These PCBs are manufactured using the maximum amount of substances as per RoHS regulations to prevent pollution. Compliance with RoHS restrictions also protects the health and safety of those who are involved in the assembling of PCBs.

By using the services of a PCBA manufacturer that is RoHS approved, you can rest assured that your products are safe and lead-free.