Printed circuit boards are the lifeblood of all mechanical and electronic devices. As such, buyers are always looking for ways to purchase PCBs on the cheap. A key to getting their business? Design a cheap PCB so you can reduce the costs passed onto the customer.

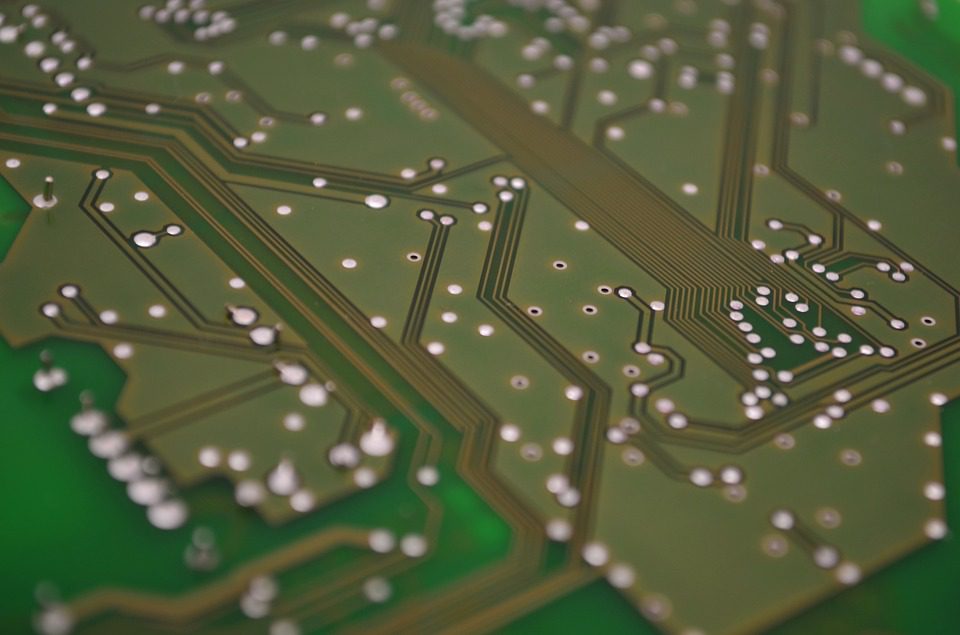

(Pixabay / RandnotizenORG)

Fortunately, there are a number of ways to make a cheaper PCB without affecting the functionality of the finished unit. This means the customer gets the same performance at a lower price. Below, we reveal secrets to making printed circuit boards on the cheap. Buckle up!

Go for the standard color

Green is the most commonly used color for solder masks while white is used to portray the legend. The majority of PCB manufacturing processes are optimized to produce solder resists and legends in these two colors. If you want to make the appearance of your board unique by modifying its color, make sure there’s a necessity because it will come at an extra cost.

Standard shapes are a good idea, as well

Standard square and rectangular PCB shapes are always cheaper to design than non-standard shapes. This is because the latter incurs upcharges by PCB fabricators. Also, try avoiding cutouts and slots unless they are necessary. There will be cases where paying a fabricator for cutouts and other modifications will be vital. However, when there is no crucial reason why the board should be non-standard, always choose a standard shape to lower your overall costs.

Integrate regular vias

From the 3 vias available, there are cost variances depending on your choice. Complex high frequency and high-density boards require the use of buried and blind vias. If your PCB design is basic (more than 90 percent of PCBs designed are simple), consider using regular through-hole vias. Using buried and blind via types in a basic design could increase your PCB expense by more than 25 percent.

Minimize PCB thickness tolerances

Although tight tolerances for PCB thickness may improve the board’s performance, it will certainly increase the costs in the PCB design phase. Therefore, it’s suggested that you go for tight tolerances only when customers specifically request them. Otherwise, a restriction is the best policy when it comes to thickness tolerances.

Consider larger dimensioned copper components

Did you know that PCB costs rise as the separation and size of the copper components shrink? The reason for this is that parts printing with smaller dimensions demands high-precision machinery. The machinery, while capable of handling the tiniest of tolerances, adds to the board’s cost. The expense is further escalated when you are designing boards that generally have low production volumes.

Use a single layer when possible

The layout of the PCB layers is another area that can help reduce the expense of its design. The cost rises with the addition of layer counts because it multiplies the charge of printing the board.

Choose a minimum surface area and set minimum spacing/clearance

The larger the surface area’s dimensions, the more the expense. By giving careful consideration to component routing and placing, you can keep the space to the minimum. Regardless of the PCB’s shape, the rectangular box will encompass the shape paid for. Hence, make your circuit board rectangular if you want to get the most out of the area you get for your money. Additionally, choose spacing and track width dimensions that enable you to complete the design comfortably. The further away the spacing, the lower the cost of your printed circuit board when it reaches the manufacturing stage.

Via and pad holes can be the same size

PCB costs often change based on how many types of via and pad holes are in its design. For example, if a printed circuit board is using a 0.2mm hole size and a 0.5mm size on the same unit, this will likely result in higher costs. A simple way to design a cheap PCB is to set the holes at the same size.

Incorporate large diameter holes

When possible, incorporate bigger diameter holes in your design. That’s because special machines are required for smaller holes, so fabrication firms will levy an upcharge for holes below 0.4mm. The same applies for minimum annular rings, which shouldn’t be smaller than 0.3mm if you want to design a cheap PCB.

It’s not impossible to design PCBs on the cheap while keeping them working as intended. The above measures are the best way to offer a low price. Of course, using turnkey PCB assembly solutions like ours may equip you with more ways to lower overall costs.