Modern PCBs operate at speeds and densities that make signal integrity problems much more likely. Design approaches that worked fine for slower circuits can cause serious issues when applied to higher frequencies.

Take a typical high-speed digital circuit. Trace routing that looks perfectly reasonable can create reflections that corrupt your data. Clock signals that should be clean may develop jitter. Power planes that appear solid may bounce all over the place.

The old approach of following design rules and hoping for the best doesn’t cut it anymore. You need to see what’s happening to your signals before you build the board. That’s where signal integrity simulation comes in.

(KamranAydinov/Freepik)

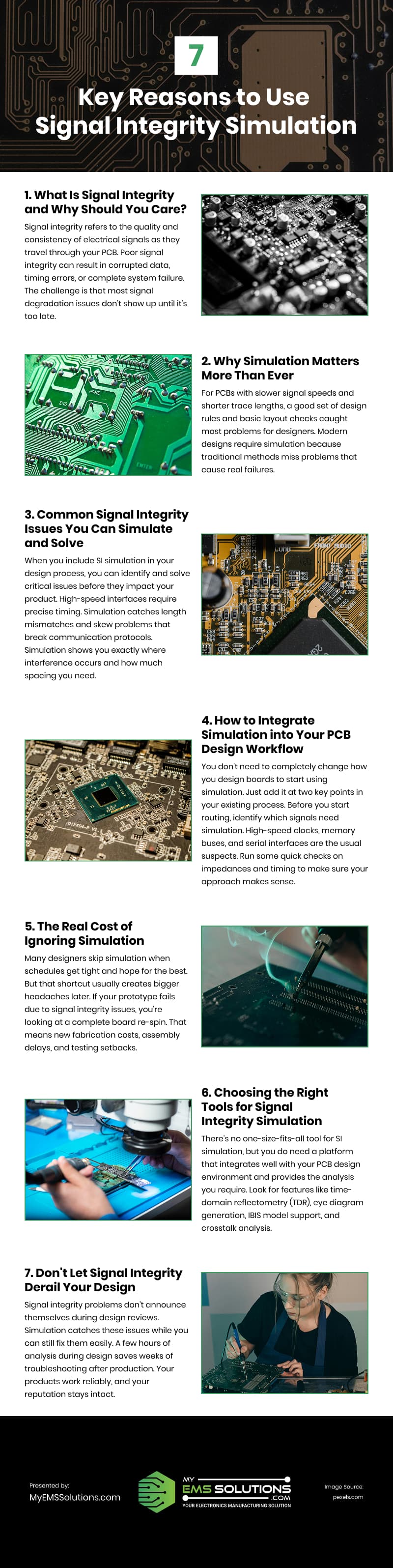

What Is Signal Integrity and Why Should You Care?

Signal integrity refers to the quality and consistency of electrical signals as they travel through your PCB. Poor signal integrity can result in corrupted data, timing errors, or complete system failure. The challenge is that most signal degradation issues don’t show up until it’s too late.

You may have seen glitches during hardware validation and assumed they were due to component failures. But often, they’re symptoms of poor SI design: a stub too long, a return path issue, or a routing error that caused unexpected reflections.

When you simulate signal behavior before prototyping, you get visibility into how your design performs under real-world electrical conditions. That knowledge helps you identify and correct problems before they become expensive headaches.

Why Simulation Matters More Than Ever

For PCBs with slower signal speeds and shorter trace lengths, a good set of design rules and basic layout checks caught most problems for designers. But now that you’re working with gigahertz-range signals, fast edge rates, and dense multilayer boards, assumptions are no longer good enough.

Modern designs require simulation because traditional methods miss problems that cause real failures. You can’t rely on visual inspection or rules-based DRC alone to catch high-speed signal issues. Here’s why:

- High-Speed Interfaces Demand Precision: DDR, USB 3.x, PCIe, and other high-speed interfaces don’t tolerate sloppy routing. Signal timing and voltage margins are so tight that even a slight impedance mismatch can break communication.

- Physical Layout Impacts Performance: Even perfect schematics can fail if your physical layout introduces discontinuities or coupling between signals. Simulation allows you to see the electrical reality of your layout.

- Short Design Cycles Leave No Room for Error: You don’t have time for multiple prototype spins. Simulation helps you get the design right the first time, reducing time-to-market and saving costs.

- Complex Stack-Ups and Layer Transitions: With HDI boards, controlled impedance stack-ups, and frequent via transitions, your signals face obstacles that aren’t obvious without modeling their behavior.

Common Signal Integrity Issues You Can Simulate and Solve

When you include SI simulation in your design process, you can identify and solve critical issues before they impact your product:

- Impedance Mismatches: Your simulation reveals where trace impedances don’t match your target values, causing signal reflections that corrupt data integrity.

- Crosstalk Between Traces: Dense PCB layouts create coupling between adjacent signals. Simulation shows you exactly where interference occurs and how much spacing you need.

- Timing Violations: High-speed interfaces require precise timing. Simulation catches length mismatches and skew problems that break communication protocols.

- Via and Layer Transition Issues: Stack-up changes and via stubs create discontinuities that act like filters or antennas, degrading your signal quality.

When you work with an experienced electronic manufacturing services partner, they can help you catch these issues during the design review process, ensuring your boards function reliably from day one.

How to Integrate Simulation into Your PCB Design Workflow

You don’t need to completely change how you design boards to start using simulation. Just add it at two key points in your existing process.

Before you start routing, identify which signals need simulation. High-speed clocks, memory buses, and serial interfaces are the usual suspects. Run some quick checks on impedances and timing to make sure your approach makes sense.

After routing, simulate your actual layout. This tells you if your trace routing and via placement are causing problems. Most PCB tools can either simulate directly or export files to simulation software.

When you send boards out for manufacturing, include your simulation constraints. Your PCBA manufacturer needs this information to build boards that actually work the way you designed them.

The Real Cost of Ignoring Simulation

Many designers skip simulation when schedules get tight and hope for the best. But that shortcut usually creates bigger headaches later.

If your prototype fails due to signal integrity issues, you’re looking at a complete board re-spin. That means new fabrication costs, assembly delays, and testing setbacks. If you’re close to production, those delays become expensive fast.

Customer failures hurt even more. Field returns, warranty costs, and reputation damage add up quickly. A product launch that stumbles because of preventable signal integrity problems can set your project back months.

The time you spend on simulation pays off. It reduces risk, improves your success rate, and gives you confidence your design will perform in the real world.

Choosing the Right Tools for Signal Integrity Simulation

There’s no one-size-fits-all tool for SI simulation, but you do need a platform that integrates well with your PCB design environment and provides the analysis you require. Look for features like:

- Time-domain reflectometry (TDR)

- Eye diagram generation

- IBIS model support

- Crosstalk analysis

- Reflection and impedance matching tools

If your designs involve advanced interfaces like DDR5 or PCIe Gen 5, you’ll need tools that model multi-gigabit signals accurately. Fortunately, many leading ECAD platforms offer built-in or add-on SI simulation packages, making it easier than ever to build simulation into your standard workflow.

You can also partner with a PCB assembly manufacturer that offers simulation support or works directly with your design team to ensure layouts meet SI targets.

Don’t Let Signal Integrity Derail Your Design

Signal integrity problems don’t announce themselves during design reviews. They show up in the field when products start failing unexpectedly. By then, you’re dealing with warranty claims, customer complaints, and emergency redesigns.

Simulation catches these issues while you can still fix them easily. A few hours of analysis during design saves weeks of troubleshooting after production. Your products work reliably, and your reputation stays intact.

The complexity of modern PCB designs makes simulation a necessity. When you make it part of your standard process, you prevent costly field failures and deliver quality consistently.

Video

Infographic

As modern PCBs push the limits of speed and complexity, signal integrity issues become increasingly critical. Traditional design rules alone cannot keep up; accurate signal behavior analysis is now essential. This infographic outlines why signal integrity simulation is a must for today’s high-performance designs.