The electronic manufacturing industry has been revolutionized by the introduction of surface mounting technology, which has proved to be better than the traditional through-hole technology. Surface mount assembly allows components to be mounted directly on the surface of the board without the need for drilling holes. The use of wires directly connecting the top and bottom sides has been eliminated with SMT. The new technology allows for a variety of options for circuit design and printing.

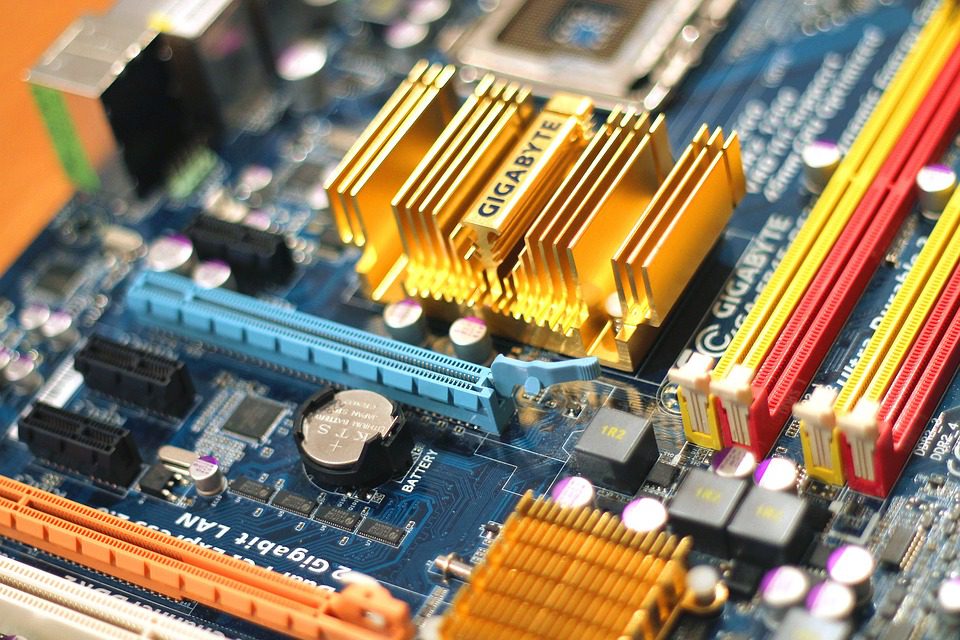

(Pixabay / StockSnap)

Here’s a closer look at the benefits of surface mounting technology:

- More space for attaching components – The traditional way of drilling holes into the circuit board monopolizes the bottom of the board for wiring. Both the top and the bottom of the board are open for component mounting when SMT is used. This means that more systems could be packed onto a single circuit board.

- Eliminates the need for drilling too many holes – The strength of the circuit board is significantly diminished every time a new hole is drilled into it. Too many holes will increase the risk of fractures on the circuit board. SMT requires very few holes, preserving the strength of the circuit board.

- Less vibration – With through-hole technology, wires commonly come loose. This is due to the frequent vibration experienced on a through-hole circuit board. The SMT minimizes vibrations which help keep wires in place.

- More rapid prototyping – It is easier and faster to make prototypes of circuit boards that use surface mount technology. A full prototype of an SMT circuit board could be completed in a matter of a few days. It commonly takes up to a week to finish a prototype with the through-hole method.

- Better outcomes – Products that use SMT circuit boards are generally superior to those that were manufactured using the through-hole method. The products are stronger and more compact with firmer wire attachments.

If your manufacturing method is still reliant on the old through-hole technology, look ahead and make plans to shift to surface mount technology.