Technology affects many industries, but its impact is especially profound in the manufacturing sector. In the last two decades, production output has risen by nearly 50 percent, largely because of technological advances that have allowed the industry to work faster, smarter, and with greater accuracy.

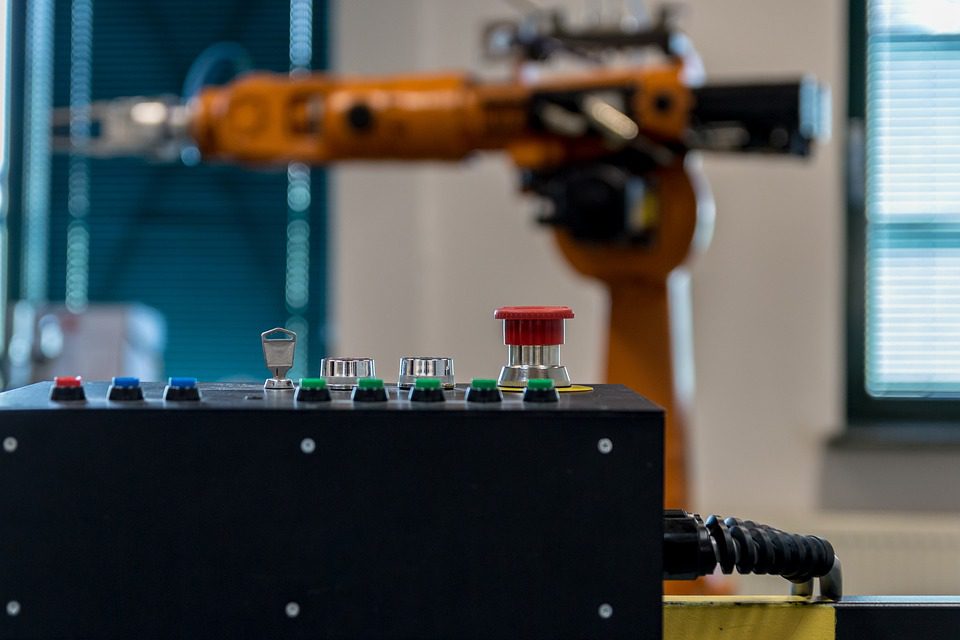

(Pixabay / jarmoluk)

So what does the future hold for manufacturing? Exciting things thanks to a number of advances. We can expect to see “giant leaps” in the field due to the following technologies:

- Industrial Internet. You have problem heard the term “Internet of Things.” There is a world of complexity behind this term, but simply put, it means connecting anything with an on/off switch to the Internet. At home, this could mean that with the help of the Internet, your coffee pot will rev up as soon as your alarm clock goes off, or if you are running out of printing ink, your computer will automatically reorder it. The Internet of Things is handy at home and indispensable on the factory floor, where the technology can be used to monitor factory assets and collect and analyze data to improve function and efficiency. For example, the Internet of Things can detect when equipment breaks and immediately notify involved parties. This can help minimize production delays, saving companies a great deal of money.

- Smart machines. In the past five years, the number of robots in the manufacturing industry has nearly doubled. Now, there are a couple million robots on factory floors. They can find and repair glitches that could otherwise go undetected for hours, baffling humans, slowing production time, wasting resources, and costing companies a small fortune.

- Cloud technology. You use it on your smart phone to store your photos and keep a backup of your data in case you lose or break your phone, but it’s also invaluable in manufacturing. Cloud computing allows manufacturers to manage and maintain important information across multiple devices.

- Wearable technologies. Perhaps the most famous wearable is the fitness tracker that monitors the amount of steps you take per day or the number of calories you have burned. Wearable devices play a large role in manufacturing, too. For example, companies are taking advantage of glasses that employees can wear to walk them through complicated tasks and allow them to leave notes for employees on the next shift. The glasses can also track pupil movement to detect when employees are getting tired. This ultimately boosts productivity and workplace safety.

There has never been a more exciting time to be part of the manufacturing industry. At EMS Solutions, we are devoted to deploying the newest innovations in technology to create better, cheaper, more efficient products for our valued customers.