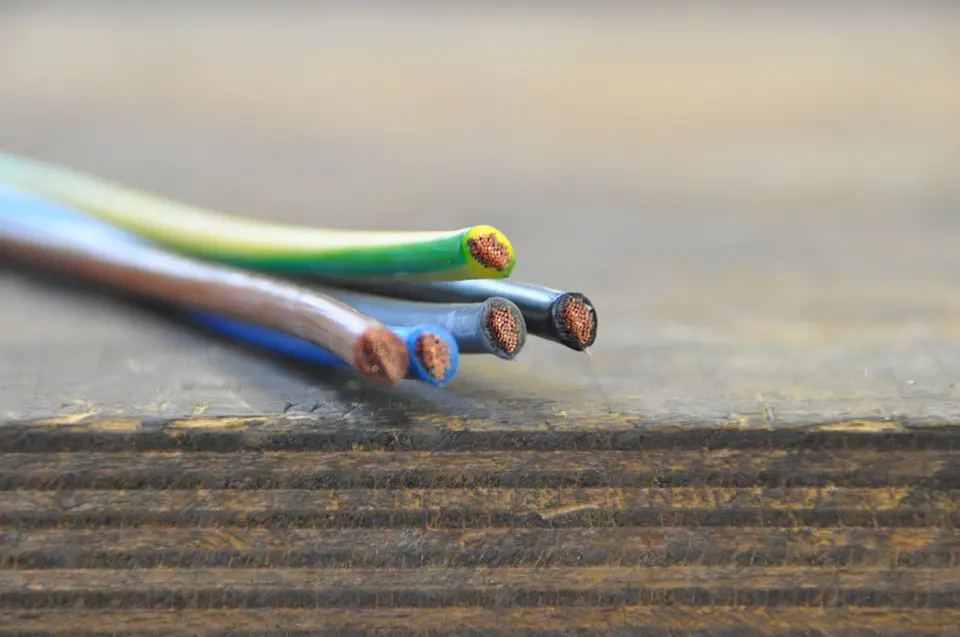

When it comes to custom assembly, jacketed cables offer a number of advantages. A jacket covers the cables, shielding them from external elements. Without the jacket, inner wires could get caught on other components, causing the assembly to fail long before its intended expiration date. The jacket can be flame-resistant, mitigating fire risks.

(Pixabay / webcreare)

There are different types of cable jackets, including cable sheaths, looms, wraps, and tubing. Several factors should be taken into consideration when deciding which materials are best for jacketed cables. These include:

- National Electric Code standards. The NEC standards are established regionally. They outline regulations for properly installing electrical wiring and equipment. Jacketed cables must be designed with strict adherence to these standards.

- Intended environment. The big question that cable designers and manufacturers must ask themselves is where a cable will be installed. This will help determine which materials are best for the cable. Cables that work well in one environment may be a poor choice for another environment.

- Special conditions. Complying with NEC standards is usually sufficient, but occasionally, cables will be needed in very specific environments. For example, if a cable is being used in a healthcare facility, it may need to be able to withstand sterilization.

- Appearance. The function of the jacketed cable is a top priority, but appearance matters as well. Customers may want a jacket to hide twists in the cable or other imperfections. They may want a matte finish or a glossy one. Perhaps color matters to your client for cosmetic reasons. They may even request a jacket that coordinates with their company logo.

- Identification. If a number of assemblies are placed close together, different colored jackets can help distinguish one assembly from another.

Consider jackets for cables in custom assemblies. They make for longer-lasting, safer, and better-looking assemblies. Contact EMS Solutions for questions about jacketed cables, box build assemblies, surface mount assemblies, and more.