People often use the terms cable assembly and wire harness interchangeably, thinking they refer to the same thing. This confusion stems from their similar applications—both are used to conduct electricity or transmit signals and to protect and organize wires. Despite these similarities, cable assemblies and wire harnesses serve very different purposes.

(Bru-nO/Pixabay)

What is a cable assembly?

Cable assemblies wrap wires or cables in strong protective materials like thermoplastic rubber or vinyl. These assemblies guard against harsh conditions, including heat, moisture, and physical wear. Designers tailor cable assemblies for specific environments, ensuring they can withstand the particular challenges they will face.

What is a wire harness?

Wire harnesses, on the other hand, gather cables and wires under a single thermoplastic cover. They aim to organize and slightly shield these components. Each wire inside this setup keeps its own insulation. The main purpose here is neat organization. While wire harnesses make wire management cost-effective, they don’t offer much in terms of protection from extreme wear or environmental changes.

Key Differences

Cable assembly and wire harness differ in the following aspects:

Materials

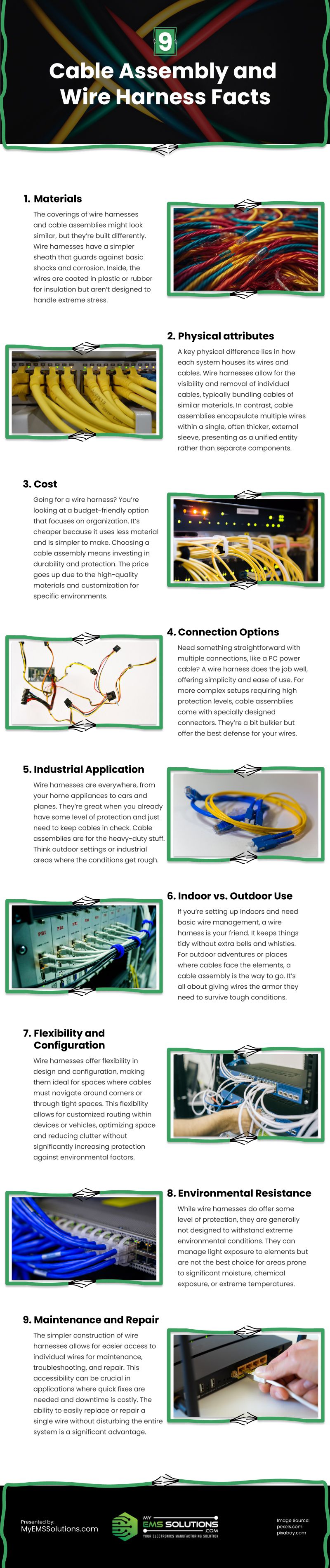

The coverings of wire harnesses and cable assemblies might look similar, but they’re built differently. Wire harnesses have a simpler sheath that guards against basic shocks and corrosion. Inside, the wires are coated in plastic or rubber for insulation but aren’t designed to handle extreme stress.

Cable assemblies, however, pack a tougher punch with materials like vinyl or thermoplastic rubber. They’re made to resist stress, heat, moisture, and more. Inside, you might find fillers like nylon or Kevlar to beef up protection, plus specialized connectors and terminations tailored for specific settings.

Physical attributes

A key physical difference lies in how each system houses its wires and cables. Wire harnesses allow for the visibility and removal of individual cables, typically bundling cables of similar materials.

In contrast, cable assemblies encapsulate multiple wires within a single, often thicker, external sleeve, presenting as a unified entity rather than separate components. This distinction highlights their differing approaches to protection and organization.

Cost

Going for a wire harness? You’re looking at a budget-friendly option that focuses on organization. It’s cheaper because it uses less material and is simpler to make.

Choosing a cable assembly means investing in durability and protection. The price goes up due to the high-quality materials and customization for specific environments.

Connection Options

Need something straightforward with multiple connections, like a PC power cable? A wire harness does the job well, offering simplicity and ease of use.

For more complex setups requiring high protection levels, cable assemblies come with specially designed connectors. They’re a bit bulkier but offer the best defense for your wires.

Industrial Application

Wire harnesses are everywhere, from your home appliances to cars and planes. They’re great when you already have some level of protection and just need to keep cables in check.

Cable assemblies are for the heavy-duty stuff. Think outdoor settings or industrial areas where the conditions get rough. They’re built to protect against just about anything the environment throws at them, making them perfect for sectors like construction, military, and medical.

Indoor vs. Outdoor Use

If you’re setting up indoors and need basic wire management, a wire harness is your friend. It keeps things tidy without extra bells and whistles.

For outdoor adventures or places where cables face the elements, a cable assembly is the way to go. It’s all about giving wires the armor they need to survive tough conditions.

Flexibility and Configuration

Wire harnesses offer flexibility in design and configuration, making them ideal for spaces where cables must navigate around corners or through tight spaces. This flexibility allows for customized routing within devices or vehicles, optimizing space and reducing clutter without significantly increasing protection against environmental factors.

Conversely, cable assemblies are less about flexible routing and more about providing a robust protective barrier. Their construction is often more rigid, tailored to specific paths that don’t require frequent bending or re-routing. This rigidity is a trade-off for the higher level of protection they afford in harsh environments.

Environmental Resistance

While wire harnesses do offer some level of protection, they are generally not designed to withstand extreme environmental conditions. They can manage light exposure to elements but are not the best choice for areas prone to significant moisture, chemical exposure, or extreme temperatures.

Cable assemblies excel in environmental resistance. They’re designed with materials and seals that can handle exposure to chemicals, water, UV light, and extreme temperatures. As such, they serve as a comprehensive protective system for any setting where environmental exposure is a concern.

Maintenance and Repair

The simpler construction of wire harnesses allows for easier access to individual wires for maintenance, troubleshooting, and repair. This accessibility can be crucial in applications where quick fixes are needed and downtime is costly. The ability to easily replace or repair a single wire without disturbing the entire system is a significant advantage.

Meanwhile, cable assemblies are generally harder to repair or modify without specialized tools or expertise. This is due to their more complex and protective construction. While this complexity provides superior protection, it can make maintenance more challenging and potentially more expensive, as the entire assembly might need to be replaced if one component fails.

Conclusion

It’s clear that while cable assembly and wire harnesses share functional similarities, their applications diverge significantly. For streamlined organization in less demanding environments, a wire harness is your go-to. But when high-quality protection against harsh conditions is paramount, opting for cable assembly manufacturing is the better choice. Making the right selection based on your project’s specific needs is key to ensuring a successful and reliable end product.

Video

Infographic

People often confuse “cable assembly” and “wire harness,” thinking they are the same due to their similar applications. However, they serve different purposes. Learn more about their differences in this infographic.