PCB manufacturers are always looking for ways to boost efficiency and production volume. What’s one quick way to improve reliability of the boards? Cleaning.

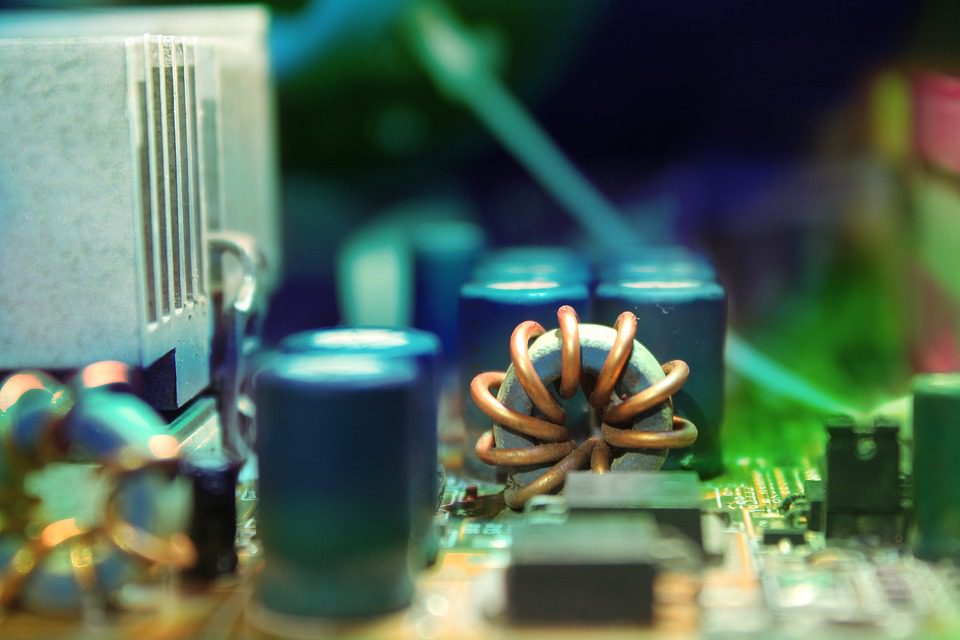

(Pixabay / CompileIdeas)

Printed circuit boards can become soiled with dirt, solder, or flux from handling. Contaminates in the environment, like dust, moisture or oxides from fingerprints can also reduce the lifespan of a PCB once it’s installed in the end device. Plus, some pollutants may have erosive characteristics, leading to the damage of connections and circuits down the road. The thorough cleaning of the PCB is an effective way to eliminate these debris and ensure there are no faults in its function.

In this post, we will discuss some common PCB contaminants and the right ways to clean them. Let’s get started.

Common Contaminants in PCBs

PCBs are delicate and getting smaller in size to accommodate handheld devices. As the devices get smaller, the size of contaminants gets larger and constant heat becomes an issue. Since every PCB component dissipates heat, the heat builds up beyond tolerance and may affect the vulnerable components. It is more important than ever to watch out for and address any red flags to prolong the life of your printed circuit board.

Dust

Dust encompasses various organic and inorganic matters and salts that can harm the quality of a PCB. Dust can build an electrolyte film on the circuit board as well as affect insulation resistance between two conductors. Particles can also increase friction on the surface that can lead to signal interference. If left unmonitored, dust on PCBs can cause irreversible damage when the device overheats.

Flux Residue

Fluxing is a process applied during the production of PCBs, and it often leaves a residue behind. This residue, when detached from the board during soldering, accumulates on the components, resulting in connectivity issues. In addition, the residue can generate current and disrupt communication. As more heat builds up on the PCB, this residue may detach and reattach on other components and eventually lead to a malfunctioning device.

Other Wet Contaminants

High temperature can turn some PCB components into a moist layer that attracts contaminants. This can also cause a grimy substance to build on the PCB, which is not easy to wipe off. You’ll need expert advice or professional help to remove such grime and protect all miniature circuits of a PCB.

How to Clean a PCB

As described above, each contaminant requires a different level of cleaning. However, you must consult with an expert before trying to clean a PCB at home. Cleaning any circuit board is no easy feat because a single mistake can cause a loss of the device. Therefore, you must ask yourself first if the risk is worth jumping into, or is it better off in the hands of an expert?

As specialists in PCB assembly, we are very familiar with the processes required for successfully cleaning a PCB. Here are a few steps for you to follow based on common contaminants.

Cleaning Dirt from a PCB

Your secret weapon for cleaning a dirt-covered PCB is a good old toothbrush. Like most other things, a toothbrush can clean the PCB without damaging its sensitive components. Use a gentle air source to blow the particles away as you clean the PCB. Avoid using a vacuum to blow air as it can build static on the PCB surface.

Cleaning Grime for a PCB

Grime can be caused by anything, from soda to wax or even oils. Removing this contaminant takes more effort than a toothbrush swipe. First, you need to remove the sockets from the PCB and set them aside for cleaning. Make sure you note where the sockets were attached or make a map on a notebook so you can reattach the sockets perfectly.

Non-phosphate detergents are great grime-fighters. Immerse the PCB in the solution and let it sit for a few minutes before you gently wipe the grime away. Then rinse the board and wipe it with fiber-free cloth. Airdry it for almost an hour so that it is good to put back in the device. Before you attach it back, check for any signs of damage.

Cleaning Flux Residue

Flux residue can be removed with the help of a saponifier. Household rubbing alcohol is your go-to material if you are DIY-ing the cleaning process. Immerse your toothbrush in the alcohol and start gently rubbing it on the board.

You can also use anhydrous alcohol for cleaning household devices (consider it as an upgraded version of a saponifier). You can also discuss it with an expert and get the best-suited saponifier for the PCB online. These are pro-grade cleaners especially created for getting unwanted reside off of PCBs.

Removing Corrosion

If the PCB is corroded with materials like battery water or salts and is within the range of being rescued, don’t send it for a professional cleanup. Instead, neutralize the substance by mixing baking soda with water and apply this mixture to the corroded area.

If the acids are significant, you may have to soak the board in the mixture before cleaning. Rinse and air dry the board thoroughly before putting the circuits back.

Ultrasonic Cleaning

Ultrasonic cleaning is a great option for cleaning very complex or dense boards of both liquid and dry contaminants. With the right ultrasonic cleaning device, the process is rather simple. Once you start it and configure the settings, the device works by utilizing high frequency to create bubbles that cleanse the board’s surface. The best thing about these bubbles is that they can reach even the tiniest of places, unlike the bristles of a brush.

It’s worth mentioning that some PCB manufacturers opt to avoid ultrasonic cleaning because the high frequencies can damage the connections or components on the board. As such, measuring the risk of a soiled component versus a damaged component is a critical factor when deciding whether to use the ultrasonic cleaning method. Ideally, it should be limited to dense printed circuit boards where a brush cannot reach.