When creating a printed circuit board, specifying the copper weight is one of the first steps.

Copper weight of any trace has a direct relationship with the amount of current it carries across the board. The ability to carry current in a trace is determined by its cross-sectional area and length, the current flow time, and temperature of the trace.

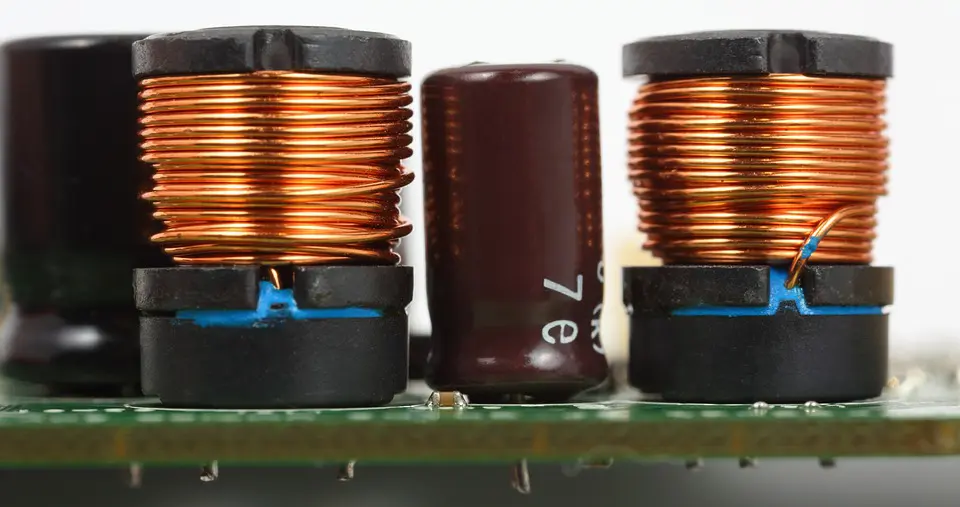

(Pixabay / nanoslavic)

Current conduction also depends on whether the trace is between a layered circuit board or in an exposed circuit board. Other factors affecting the current carrying capacity of a trace are the components and pads on a circuit board.

Why Copper Weight Matters

Copper is one of the most significant features of a PCB because it is a massive conductor. Not choosing to weigh the copper can result in various problems during PCB manufacturing. Because copper makes the foundation of any PCB, it connects to everything around it. Correct calculations of the copper’s weight make it easy to manufacture the board with minimal error.

It sounds like a simple task, but there are some things you must know about copper as a metal that affect correct calculations. Firstly, copper is an alloy like any metal, which is one of the reasons why it plays the role of a conductor. Also, it’s a common and readily available alloy found in the market. You must know the grade and what form the alloy will take to calculate the weight itself. Other measurements involve the physical state of copper.

Designing PCBs with Heavy Copper

The thickness of copper is measured in ounces. The thickest copper can weigh as much as 19 ounces per square foot. It is a common choice for PCBs since most of today’s devices are compact and require microchips. Other weights of copper are also used in PCBs, but heavy copper has become a norm. Heavy copper also offers more flexibility in designing PCBs. Manufacturers are able to diversify the looks of PCBs because heavy copper is a very versatile alloy in production.

Another reason behind the wide usage of heavy copper is that it takes up a small space on the circuit board. This helps open doors to more PCB designs. Diversifying or creating new designs with heavy copper is no longer challenging when you have access to a strong directory of required copper weight.

How to Specify Copper Weight in PCBs

There are three specifications of copper weight that must be noted before moving on to production. Based on weight, copper is classified into three grades, and each of them has a critical role in PCB manufacturing. Since copper is a strong conductor of current, it is not necessary to weigh it in square inches, so it can be measured in ounces per square foot. Here are the three classes of copper:

Standard

Copper plating that ranges from ¼ of an ounce per square foot to 4 ounces per square foot is included in the standard class. This measurement was the norm for a very long period. Why? Because the risk of failure is very low when it’s used to plate a PCB. Even today, you’ll see many manufacturers using standard class copper. In fact, if someone does not specify the copper class, it is assumed to be this one.

Heavy

A copper that weighs 5 to 19 ounces per square feet is identified as heavy copper. Designers love to experiment with heavy copper to diversify their PCB designs. In many cases, heavy copper is superior to standard copper and provides more room to create and experiment.

Extreme

Beyond heavy copper, PCB designers were keen to experiment with a grade that could create more powerful and lasting designs. This is how extreme copper came into being. It weighs 20 to 200 ounces per square foot and can be used in PCB manufacturing by restricting the charges yielded by this grade. Using a technique called Powerlink, you can place two copper weights on the same PCB layer, thereby eliminating the need to have various standard copper plates. In simpler terms, it allows you to just place a smaller quantity of extreme or heavy copper plates on the outer layer of the board.

PCBs with a higher copper weight will be able to carry more current. Plus, they look much better and are every bit as efficient as PCBs utilizing standard copper.

We hope that this post familiarized you with the importance of copper weights in PCB design and manufacturing. If you want to know more about the role of copper in electronic manufacturing services, contact us at 801-543-9445.