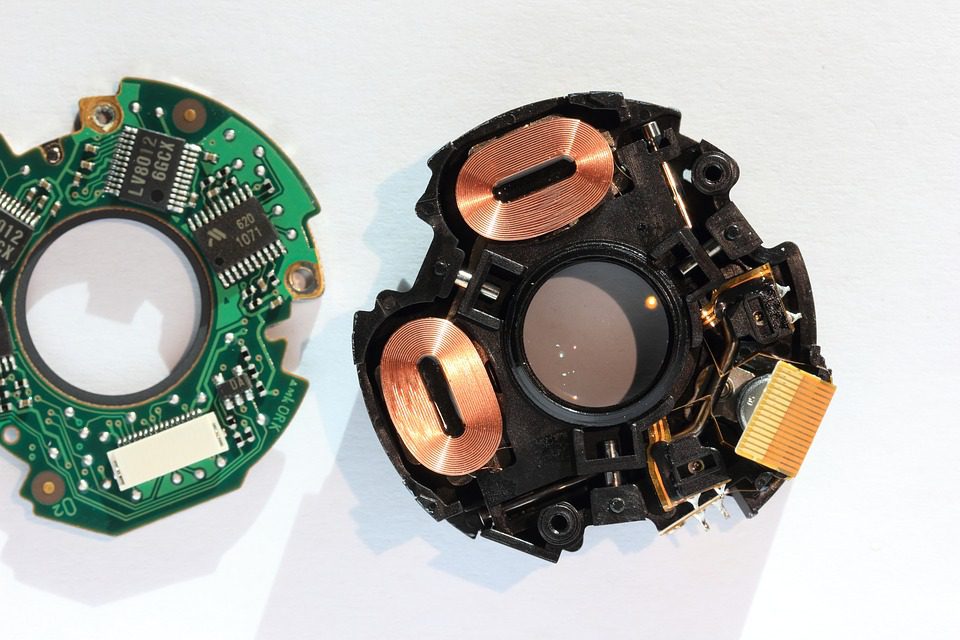

Assembling printed circuit boards is no easy task. It requires a myriad of complex procedures, a skilled labor force and sophisticated machinery.

(Pixabay / olafpictures)

Companies that demand PCB assemblies know how costly the process can become. The priority, therefore, is to modify the circuit design to slash the assembly bill and work with the right vendors and manufacturers.

This post discusses the most effective ways to save on PCB assembly orders with the assurance of high quality. By the time you finish reading this article, you’ll have a good idea of what steps to take to keep PCBA expense to a minimum.

Let’s cut to the straight to the list:

1) Ensure the rings and holes are sized right

Annular holes and rings should smoothly fit the circuit board and be as big as the customer requires. Larger hole diameters are cost-friendly because they don’t involve the use of precise equipment. Smaller rings and holes, on the other hand, require vigilant options and control, which means higher PCB assembly and manufacturing costs.

2) Conduct a DFM check and optimize the schematic design

The second step before the actual assembly is to verify whether your PCB can be implemented in a standardized manner, which is also known as a DFM (designed-for-manufacturing check). Several PCB assemblers offer a free designed-for-manufacturing check service, which customers can rely on to bring down costs. Specific measures, like calculated arrangement of layers and blind vias, can also help reduce the price of your bare PCBs.

3) Plan order volume according to your needs

PCBA order volume is often inversely proportional to the cost of each item. The bigger the order volume, the more affordable it gets for circuit board assembly customers (the same applies to the manufacturing of PCB units). Hence, it’s a good idea to take your firm’s standing into account, and know whether your order volumes will be low, medium or high. This should make it easy to pick a PCB assembly vendor who can cater to your current needs.

4) Skip cutouts where possible

Saving on PCB assembly means forgoing non-essentials. Let go of internal cutouts unless they’re an absolute necessity for PCB mounting. Many companies will quote a higher price when they’re asked to make a slot or perform other cuts in your PCB board. Also, some designers may try to achieve something unique but standard, which is often enticing for engineers but won’t likely bring much difference in your brand image or functionality.

5) Be smart about lead times

When it comes to PCB lead times, the core issue is with its calculation. It’s common to see customers get confused by attractive lead time promises. In reality, different PCBAs make different calculations for lead times, so it’s critical to know the following: What is the day you place an order and the day to make the payment? When does the assembly start? What week do the components arrive? The rule of thumb here is that the longer the lead time, the lower the cost.

6) Provide a full and accurate BOM

The BOM or bill of materials is a list of components and other essentials required for PCB assembly. It includes critical information on assemblies and sub-assemblies, items, component replacements, part numbers, raw materials, and more. Try to accurately list all the required details when sending the BOM to minimize back-and-forth time. In many instances, a PCB assembler will provide you with their own BOM guidelines and/or template, which you can complete accordingly to speed up the overall process.

7) Don’t ignore testing or inspection

Testing or inspection plays a critical role in PCB assembly savings by highlighting mistakes or issues in advance. Some assemblers will offer this service as part of the package, while others may refer you to a third-party inspection company. It’s more efficient and convenient to have the products tested on the vendor’s premises. In such cases, the assembler will usually charge a lower fee than those only specializing in PCB inspection. Costs also go down as the PCB unit doesn’t need to be delivered anywhere.

8) Take advantage of the vendor’s component sourcing

Component sourcing is one aspect of PCB assembly that demands a lot of dedication and time. Problems like obsolete components will complicate things and lead to further headaches. For these reasons, it’s best for small-to-midsized companies to count on vendors to resolve these issues. Fortunately, most PCBA vendors provide some strategic sourcing service and can often purchase components at wholesale prices.

9) Choose the right PCBA manufacturer

The last step to saving on PCBA is to choose a reliable PCB assembler/manufacturer. Several companies claim to provide cost-effective PCBA manufacturing but leave customers unsatisfied as they don’t deliver on their promises. To avoid these kinds of issues and improve your bottom line, work with companies like EMS Solutions.

Armed with the tips mentioned above, you’ll be able to bring down your PCB assembly costs in no time.