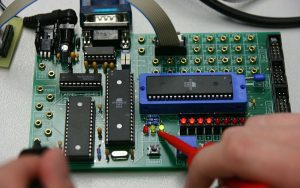

The final stages of manufacturing printed circuit boards, or PCBs, involve testing to ensure that all components are correctly connected in place. These tests can run in several ways, from a simple look-over to more specific connection tests.

Two of the more popular tests used are in-circuit testing (otherwise known as the bed of nails test) and flying probe testing. Both tests are designed to run currents through the testbeds of PCB components, allowing testers to determine the strength of their connections.

(delphinmedia / pixabay)

Much like its nickname suggests, ICT or the bed of nails involves placing a completed PCB on a bed of pins. The pins form connections with each of the testbeds, allowing the tester to run currents through each component and test their strengths.

Recently, though, a new form has changed the face of PCB testing. That is flying probe testing, and here we will look at how it works.

How Flying Probe Testing Is Done?

A flying probe test is conceptually the same as a bed of nails fixture test, and it involves checking the connections of each chip in a board by running a current through them. However, a flying probe uses a mobile header where a bed of nails involves pins that connect every connection simultaneously. This is a set of pins attached to an arm that can move around the board to check each connection individually.

First, the testing engineer will take the computer-aided design (CAD) data for the board. This data will be run through a test program, allowing the testing unit to plot out the board and its components. This data will be compiled with data for the board, determining which areas need to be tested.

The unit under test (UUT) is inserted into the tester unit via a conveyer belt. The probes are programmed along the board’s X-Y axis, which moves the headers from point to point along the board. The probe runs a current through each connection and back through a multiplexing system and sensors. These sensors are usually digital multi-meters or frequency counters, which will measure the signal. Each other component on the UUT is shielded from the current, which prevents the signal from being disturbed.

The readings gathered during these tests will alert the tester of any shorts or errors in the components. What’s more, the flying probe tester is a camera that gives them an up-close view of the UUT, allowing them to see any physical faults or missing components.

Advantages of Flying Probe Testing

As a mode of testing component boards, flying probe testing offers many advantages over other forms of testing. These advantages include:

- Short testing time – the flying probes move swiftly and accurately from component to component, keeping test time low. This is true even if retests need to be run.

- Quick feedback time for engineers – the quick speed of the tests and near-instantaneous results allow testers to get data back to engineers quickly, speeding up development time.

- Wide range of testing options – the probes can have several testing currents, such as signal generators or ac and dc power supplies.

- Lower setup and operating costs – compared to other testing options, flying probe testing is ideal for small tasks, and testing machines are easily adaptable. This helps to make it much cheaper to perform without requiring high operation costs.

Disadvantages of Flying Probe Testing

As with any system, flying probe testing is imperfect. Issues can arise, giving it a few disadvantages. These are:

- Can cause physical damage – since the probes are making physical contact with the board as they move around, there is a small chance that they may cause damage. It is not unknown for the probes to skim the board’s surface, causing pits that an amateur tester can pick up as fabrication defects.

- Can miss some poor connections – as the pads make contact, they may result in improperly formed circuits. As a result, components may test as working, but their disconnection through poor soldering might miss the mark.

Despite these potential problems, flying probe testing is still considered one of the best options for PCB fabrication. But how does it fare against the older forms of testing?

Flying Probe Testing or In-Circuit Testing (ICT)?

Conceptually, flying probe testing and in-circuit testing are very similar – both involve testing individual components through pins that complete circuits. ICT has been around much longer, but with flying probes sweeping the world of electronics, you’ll need to weigh the pros and cons based on the work you need done:

• Cost-effectiveness

Of the two options, flying probe testing is by far the cheaper option. The programmable nature of a flying probe means it is adaptable to any size or layout of the board. All you need is the corresponding CAD files. ICT, on the other hand, requires a custom setup for each board. This can be ideal if you test a high volume of boards, but the flying probe will still be cheaper from setup.

• Accessibility

ICT pins are naturally bigger than the ones found in flying probes. As a result, the pins must be custom-made for each board to ensure they fit in each test pad. On the other hand, probes are made much smaller to begin with, giving them a much greater degree of accessibility. Regardless of the board, flying probes will be ready to fit any board.

• Testing flexibility

As mentioned before, the pin bed for an ICT requires a specific setup for each board. Every time a new board needs to be tested, the tester has to reconfigure the pins manually. This makes it great for testing multiple units of a single PCB but terrible for testing multiple boards. However, testers can quickly program according to the CAD files for each board, which makes it much quicker to alter for different boards over a short period.

• Testing points

Using an ICT means that you must install specific test points into each board. These will allow the pins to connect and test the components. The probes, by contrast, can directly access component pins, meaning they don’t need any special access. This means you won’t have to build your boards according to the testing requirements.

Conclusion

In-circuit testing will always be an industry standard. However, as technology progresses and the types of boards we produce evolve, flying probe testing proves its importance more and more. If you’re looking for a quicker, cheaper turnaround of many different board tests, a test solution comprising flying probe testing can be your new ideal.

More questions? As a leading contract manufacturer in Utah, EMS Solutions is here to help you with your PCB testing questions.