A PCB is a printed circuit board that supports electronic parts and connects them through conductive tracks, pads, and other features. These features are etched onto copper sheets that are laminated onto a non-conductive, planar substrate (sometimes called a wafer).

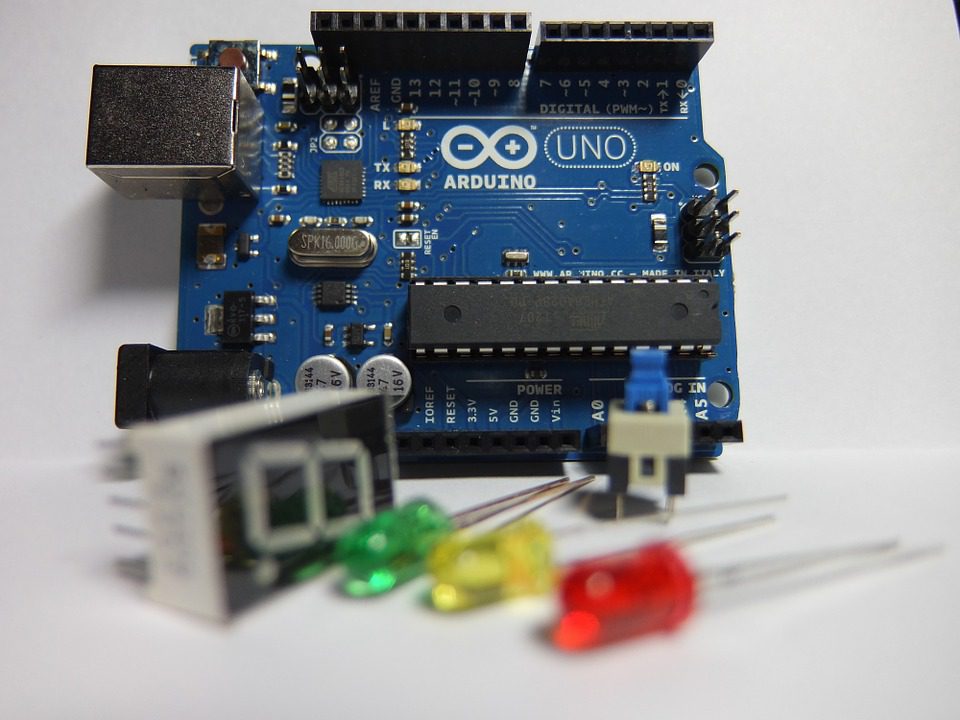

(Pixabay / tikishabudin)

PCBs are the building blocks of virtually all electronic products, including game consoles, cameras, computers, home appliances, and more. Before PCBs, there were different circuit solutions, including wire wrap which bound electronic components together on insulating boards with lengths of insulated wire. There was also point-to-point construction, which relied on large vacuum tubes with big sockets. Both of these methods were largely eclipsed by PCBs, although point-to-point is still used for heavy electronic components.

If you are working with customers, you may hear the terms printed circuit board and printed circuit board assembly (PCBA) used interchangeably, but there is a distinct difference. While the PCB is the board that enables attachments, the PCBA comprises both the board and all attached components. These components allow the board to perform its intended use.

Components may include:

- Switches—open or close to facilitate or block current

- Diode—also deals with current passage, facilitating it in one direction and blocking it in the other

- Capacitors—store electrical charges

- Transistors—amplify electrical charges

- Batteries—give circuits their voltage

- Resistors—control electrical current as it passes through

- LED (light emitting diodes)—light up when current is present

Components of a PCBA may be attached through surface mount assembly or through-hole methods. Solder is used to get the components to adhere to the board. Solder must be applied with great precision. Stray solder in unwanted places could lead to a malfunctioning board at very least and an explosion in worst-case scenarios.