The medical field demands precision and reliability at every turn. Even a minor oversight can lead to significant repercussions, endangering patients’ health. Thus, ensuring every component designed for medical devices works without fail is paramount.

Among these components, cable assembly demands careful attention. As something responsible for ensuring uninterrupted communication and power within a medical device, you can’t take any chances with your selection.

In this article, we’ll highlight the essential factors to consider when choosing cable and wire harness assemblies for medical use.

(vecstock/Freepik)

Reasons to be careful when selecting medical cable assemblies

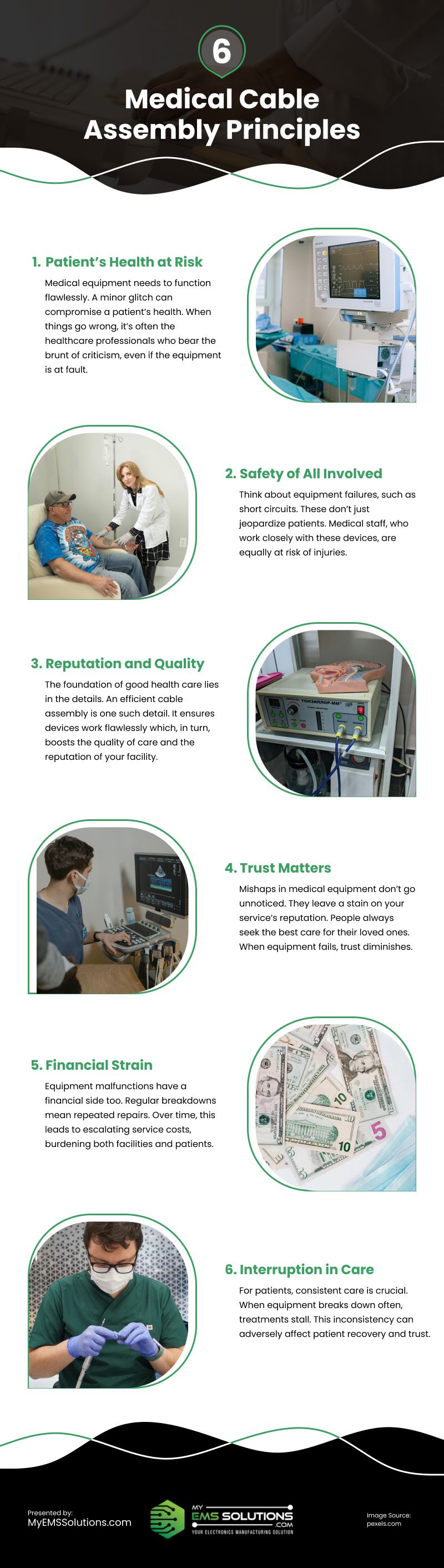

Most medical suppliers don’t give much attention to medical cable assemblies. However, it’s crucial to be extra cautious when sourcing this component for your device. Here’s why:

Patient’s Health at Risk

Medical equipment needs to function flawlessly. A minor glitch can compromise a patient’s health. When things go wrong, it’s often the healthcare professionals who bear the brunt of criticism, even if the equipment is at fault.

Safety of All Involved

Think about equipment failures, such as short circuits. These don’t just jeopardize patients. Medical staff, who work closely with these devices, are equally at risk of injuries.

Reputation and Quality

The foundation of good health care lies in the details. An efficient cable assembly is one such detail. It ensures devices work flawlessly which, in turn, boosts the quality of care and the reputation of your facility.

Trust Matters

Mishaps in medical equipment don’t go unnoticed. They leave a stain on your service’s reputation. People always seek the best care for their loved ones. When equipment fails, trust diminishes.

Financial Strain

Equipment malfunctions have a financial side too. Regular breakdowns mean repeated repairs. Over time, this leads to escalating service costs, burdening both facilities and patients.

Interruption in Care

For patients, consistent care is crucial. When equipment breaks down often, treatments stall. This inconsistency can adversely affect patient recovery and trust.

Factors to Consider When Choosing Medical Cable Assemblies

Selecting the right cable assembly manufacturer plays a critical role in the functionality and longevity of medical devices. Here’s what you need to keep in mind:

Durability of the Assembly

Durability stands front and center in considerations. The resilience of medical equipment directly ties to the quality of service provided. Even when medical staff or patients handle devices carelessly, the equipment should withstand rough use. In challenging environments, these devices must still function seamlessly. Delayed or malfunctioning equipment can jeopardize patient lives. Moreover, durable equipment isn’t just safer; it’s also cost-effective, requiring fewer repairs.

Reusability and Sterilization

Maintaining a sterile environment is paramount in medical facilities, especially in areas like ICUs and operating rooms. Equipment sterilization involves potent chemicals and procedures that many standard cables can’t withstand. While these ordinary cables may degrade with chemical exposure, medical cable assemblies are designed for reuse and can endure rigorous sterilization processes.

Signal Continuity

Signal integrity is paramount, especially with the constant demands of emergency healthcare services. A consistent, accurate power supply ensures equipment runs as it should. Any lapse in electricity, especially during emergencies, can escalate into life-threatening situations.

Chemical Resistance

Sterility in medical environments often involves chemicals. Whether for sanitation or medication-related purposes, these chemicals can pose a threat to ordinary cables. However, specialized medical cable assemblies are designed to resist a variety of chemical exposures, ensuring their longevity even in chemically-intensive environments.

Cable quality

Quality stands paramount in medical cable assemblies. At the heart of an exceptional assembly lies the conductor, which employs specific metals to transmit electrical signals to medical devices. Following closely, the insulator, crafted from polymers, acts as a shield, preventing any electrical leakage and averting potential short circuits. Then there’s the jacket, the assembly’s outer protective layer. Not only does it safeguard the internal components, but it also streamlines the handling process, especially during sterilization.

Adaptability and Custom Design

The diverse needs of the medical field require adaptable cable solutions. Unlike static standard cables, medical cable assemblies offer customizability. If existing cables fall short of your expectations, consider custom-designed medical assemblies. Such assemblies cater to specific needs, ensuring flexibility across various applications. With dedicated teams of engineers and designers, custom cable assembly manufacturers prioritize creating tailored, scalable cable solutions, allowing medical professionals to focus on patient care.

The well-being of patients is deeply connected to the equipment employed in healthcare settings. Selecting high-quality medical cable assembly services is at the core of equipment effectiveness. Its functionality must be critically evaluated, and its absolute safety ensured for everyone involved. Whether they are professionals managing the equipment or patients relying on it, no one should face any risk. Before using any assembly, make sure to inspect it, gauge its efficiency, and confirm its safety for every stakeholder.

Video

Infographic

Precision and reliability are crucial in the medical field. Minor oversights can have serious repercussions for patient safety. It’s essential to ensure that every medical device component works flawlessly. Check out the infographic for more on the importance of sourcing components carefully.