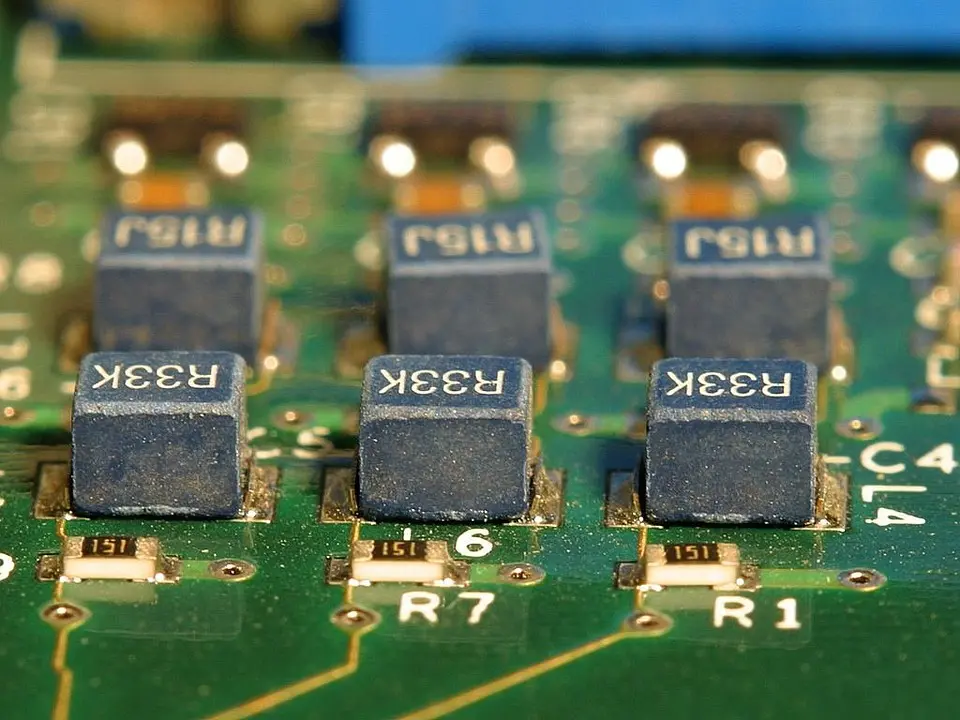

Printed circuit boards are the backbone of the electronics industry. They support and connect electronic components that are soldered onto layers of copper sheets. The soldering will anchor them to the PCB while providing electronic connection. A PCB may have one or multiple layers of copper sheets and be single or double-sided. Multi-layer PCBs were made possible thanks to surface mount technology. Being able to incorporate multiple layers onto just one board facilitates many more possibilities using much less real estate.

(Pixabay / PDPhotos)

PCBs are rapidly becoming more sophisticated, but they are not foolproof. The reality is that errors happen in the manufacturing process and circuit boards can falter.

Here are some of the most common reasons that PCBs fail:

Shoddy components and PCB assembly

The problem with your PCB may start at the most basic level if components are poorly manufactured. And even if the components are sound, they may be poorly connected if they were not soldered properly. (This may be the result of a soldering technician failing to adequately heat the solder at a connection point.) If the connection is weak, components might burn. Another problem can occur if the flux used in the soldering process is left on the board. Flux can cause a PCB to corrode.

Overheating

With all of the electrical activity on a printed circuit board, things tend to get pretty warm. If components are subjected to more heat than they can hold, due to their size or composition material or structure, they could burn. Burning also occurs when components are not spaced properly. As we try to cram more and more on PCBs, there is always the risk of overcrowding and, as a result, overheating.

Time

Nothing lasts forever—including electronic components. If one component, such as a capacitor, starts to get weary, devices will not power up properly. Fortunately, if you can identify the aging party, you may be able to replace it rather than scrapping the entire PCB.

Changes in the environment

Moisture is a PCB’s biggest nemesis. If a PCB comes in contact with moisture, it could corrode. Dust and dirt can also infiltrate equipment and cause it to fail. Temperature changes, too, can derail a PCB. When a board is exposed to significant temperature swings, it will expand and contract, damaging the soldering joints and warping the board.

While there’s no way to completely prevent printed circuit board failures, you can ensure that you order from a reliable contract electronic manufacturer. At EMS Solutions, you will find U.S. manufacturing that you can count on. We have earned ISO 9001, AS9100, IPC, and RoHS certifications and hold ourselves to the highest standards in the industry.

When you order from EMS, you can count on a top-quality, long-lasting product.