During the past few years, the electronics manufacturing industry has shown great interest in expanding the use of automation and robotics in factories, especially in regions where the cost of labor is very high. As the trend continues, we will see more integration of automated and manual assembly steps.

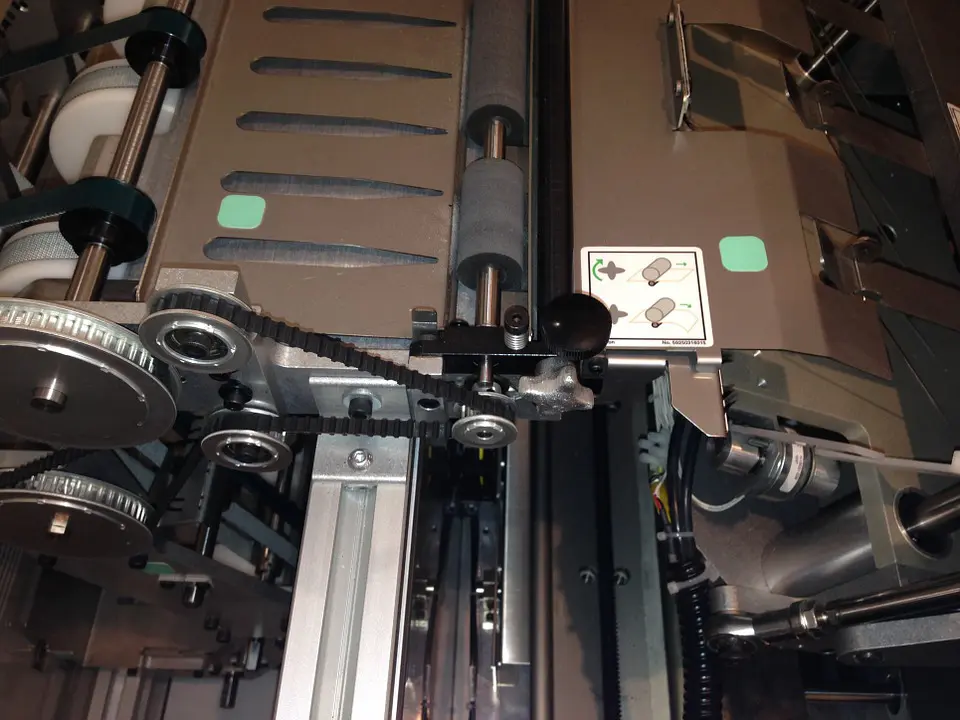

(Pixabay / DevilsApricot)

Automation is not new to electronics manufacturing. The semiconductor industry profited greatly from factories that were fully operated by machines and robots. Automation also changed the production of smart electronics, with machines being used for injection molding and the coating of enclosures.

These small steps in the electronics manufacturing industry have slowly but steadily attracted companies to hop on the automation bandwagon. There is now a trend to use automation in the fabrication of printed circuit boards. Automation is used for active and passive placement of electronic components, inspection, equipment and software testing, and packaging.

Here are some of the benefits of automation in electronics manufacturing:

- Better product quality – Automation speeds up the manufacturing process. It relieves humans of having to complete basic steps so they can concentrate on higher value activities, which include applying finishing touches and other fine details. This results in higher quality products.

- Greater productivity – Human labor comes with a high margin of error, especially on repetitive work that gives rise to boredom and loss of attention. While machines are never perfect, they are prone to fewer errors than humans. Machines don’t get bored or distracted and can get more precise work done in less time.

- Customization opportunities – Customers often request customized products. Manufacturers must be able to tailor the orders without sacrificing quality and profitability. If human workers do the customization, it will entail more work, time, and pay. Machines, on the other hand, can be programmed to fit customization requirements without expending many resources.

- Creation of new products – It is easier to roll out new products when production is automated. A few clicks and adjustments to a machine will produce new results, which can then be tested for high-quality performance.

Electronic manufacturing services and contract electronic manufacturers will greatly benefit from automation, which engenders faster production, fewer errors, and limited demands on human capital.