Original equipment manufacturers (OEMs) typically outsource their electronics manufacturing and testing, a practice that has been going on for decades. Some companies have smooth outsourcing experiences while others don’t. Because of the varied experiences, a lot of myths have cropped up in relation to electronics outsourcing.

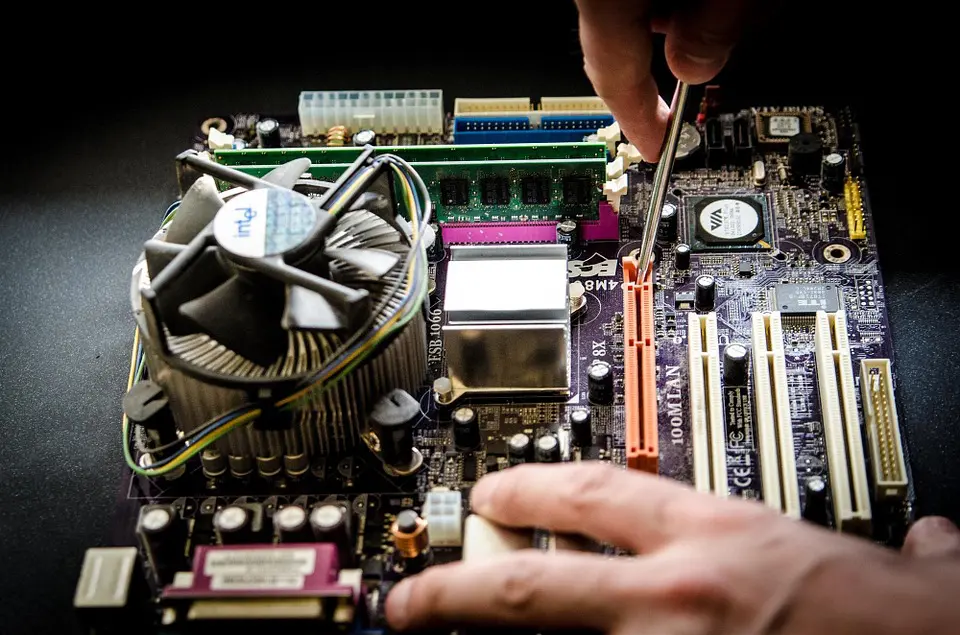

(Pixabay / jarmoluk)

Here’s a look at some of the most common myths:

- The cost of a company’s products will significantly go down when they outsource – Unit pricing is the main subject of negotiation between original electronics manufacturers and third party service providers. While the EMS provider may offer a much lower price compared to the competitors, there is no guarantee that the OEM’s products can be sold cheaper. If the OEM makes a small order of a particular product, especially one that is just being developed, there is a very slim chance that the EMS provider can offer a lower price. Even if the OEM can outsource the product at a very low cost, there are several factors within the company that might drive up the item’s cost, such as marketing and logistics.

- An OEM needs an EMS provider with a manufacturing plant in the area – Proximity of the EMS provider’s manufacturing plant used to be considered a big plus for the OEM, allowing them to send engineers and inspectors to help monitor production. But with the improvement in communications technology, distance is no longer considered an important factor in business. You can video-check something or teleconference with people in the manufacturing plant without leaving your OEM office.

- OEMs should partner with multiple EMS providers to spread the risk – This is a common practice in outsourcing. The OEM deals with several EMS providers to get the lowest cost and to guarantee that if one plant fails to deliver, other plants will continue supplying the products. But there are also downsides to this tactic. When an OEM manages a group of suppliers, it will add more work to the internal organization. There will be more people to deal with each supplier, expanding the company’s bureaucratic layers.

- The OEM’s product is too complex to outsource – Most all products—including complicated ones—can be outsourced. In today’s world, you can always find an EMS provider that can manufacture your item, no matter how intricate it is. If your company was able to create it, there is no reason why another company cannot. The EMS provider need not reinvent the wheel; they simply need to manufacture the product based on your original design and specifications.

If your company is considering outsourcing your products to a contract electronics manufacturer and you have concerns, consult professional EMS providers who can walk you through the process and help ensure the best outcome.